Iketile yeZinc

Ingcaciso yeMveliso

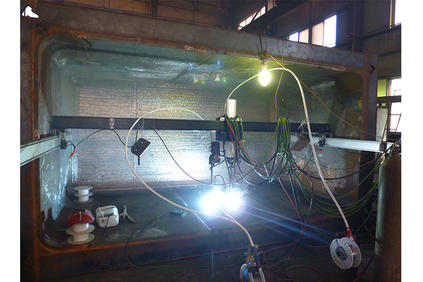

Itanki yokunyibilikisa i-zinc yokufaka i-galvanizing ye-hot-dip yezakhiwo zentsimbi, edla ngokubizwa ngokuba yimbiza ye-zinc, ubukhulu becala idityaniswe ngeepleyiti zentsimbi.Imbiza yensimbi ye-zinc ayilula nje ukwenza, kodwa ifanelekile ukufudumeza ngemithombo eyahlukeneyo yobushushu, kwaye kulula ukuyisebenzisa kunye nokugcinwa kwayo, ilungele ukuxhasa ukusetyenziswa kwesakhiwo esikhulu sentsimbi eshushu-diphu yokuvelisa i-galvanizing line.

Umgangatho we-at-dip galvanized coating kunye nokusebenza kakuhle kwemveliso kuhambelana ngokusondeleyo neteknoloji yenkqubo esetyenziswayo kunye nobomi bembiza ye-zinc.Ukuba imbiza ye-zinc idliwe ngokukhawuleza kakhulu, iya kukhokelela kumonakalo ongaphambi kwexesha okanye ukuvuza kwe-zinc ngokugqobhoza.Ilahleko ethe ngqo yezoqoqosho kunye nelahleko yezoqoqosho engangqalanga ebangelwa kukumiswa kwemveliso inkulu.

Ubuninzi bokungcola kunye nezinto ezidibeneyo ziya kwandisa ukubola kwentsimbi kwibhafu ye-zinc.I-corrosion mechanism yentsimbi kwibhafu ye-zinc yahluke ngokupheleleyo kuleyo yentsimbi emoyeni okanye emanzini.Ezinye iintsimbi ezinokumelana ne-corrosion elungileyo kunye nokumelana ne-oxidation, njengentsimbi engatyiwa kunye nentsimbi ekwaziyo ukumelana nobushushu, zinokuxhathisa umhlwa okusezantsi kwi-zinc etyhidiweyo kune-carbon low-silicon ephantsi enobunyulu obuphezulu.Ke ngoko, intsimbi ye-silicon ephantsi enekhabhoni ephantsi enobunyulu obuphezulu ihlala isetyenziselwa ukwenza iimbiza ze-zinc.Ukongeza inani elincinci lekhabhoni kunye ne-manganese () kwintsimbi kunempembelelo encinci kwi-corrosion resistance yentsimbi kwi-zinc etyhidiweyo, kodwa inokuphucula amandla entsimbi.

Ukusetyenziswa kwe-zinc pot

- 1. Ukugcinwa kwembiza ye-zinc

Umphezulu wembiza ye-zinc edlekileyo okanye erulileyo iya kuba rhabaxa, nto leyo eya kubangela ukonakala okukhulu kwe-zinc engamanzi.Ngoko ke, ukuba imbiza entsha ye-zinc idinga ukugcinwa ixesha elide ngaphambi kokusetyenziswa, amanyathelo okukhusela ukubola kufuneka athathwe, kubandakanywa ukukhuselwa kwepeyinti, ukuyibeka kwindawo yokusebenzela okanye ukugubungela ukuphepha imvula, ukupakisha ezantsi ukuphepha ukucwina. emanzini, njl. Phantsi kweemeko kufuneka umphunga wamanzi okanye amanzi aqokelele kwimbiza ye-zinc.

2. Ukufakwa kwembiza ye-zinc

Xa ufaka imbiza ye-zinc, kufuneka ihanjiswe kwisithando somlilo se-zinc ngokweemfuno zomenzi.Ngaphambi kokusebenzisa ibhoyila entsha, qiniseka ukuba ususa umhlwa, intsalela ye-welding slag spatter kunye nobunye ubumdaka kunye nezihlwayo kudonga lwebhoyila.Umhlwa uyakususwa ngendlela yomatshini, kodwa umphezulu wembiza ye-zinc awuyi konakaliswa okanye urhabaxa.Ibrashi yefayibha eqinileyo ingasetyenziselwa ukucoca.

Imbiza ye-zinc iya kwanda xa ishushu, ngoko kufuneka kubekho indawo yokwandiswa kwamahhala.Ukongezelela, xa imbiza ye-zinc ikwiqondo lokushisa eliphezulu ixesha elide, "i-creep" iya kwenzeka.Ke ngoko, ulwakhiwo olufanelekileyo oluxhasayo luya kwamkelwa kwimbiza ye-zinc ngexesha loyilo ukuyikhusela ukuba ingakhuli kancinci ngexesha lokusetyenziswa.