Ikettle yeZinc

Ingcaciso yeMveliso

Itanki yokunyibilikisa i-zinc yokufakela i-hot-dip kwizakhiwo zentsimbi, edla ngokubizwa ngokuba yi-zinc pot, idityaniswa kakhulu ngeepleyiti zentsimbi. Imbiza ye-zinc yentsimbi ayilulanga nje kuphela ukuyenza, kodwa ikwalungele ukufudumeza ngemithombo eyahlukeneyo yobushushu, kwaye kulula ukuyisebenzisa nokuyigcina ikwimeko entle, ifanelekile ngakumbi ekuxhaseni ukusetyenziswa komgca wemveliso ye-hot-dip galvanizing yesakhiwo sentsimbi.

Umgangatho we-hot-dip galvanized coating kunye nokusebenza kakuhle kwemveliso kunxulumene kakhulu neteknoloji yenkqubo esetyenzisiweyo kunye nobomi be-zinc pot. Ukuba i-zinc pot idlakazwa ngokukhawuleza, iya kukhokelela kumonakalo wangaphambi kwexesha okanye ukuvuza kwe-zinc ngokugqobhoka. Ilahleko ethe ngqo kwezoqoqosho kunye nelahleko engathanga ngqo kwezoqoqosho ebangelwa kukumiswa kwemveliso inkulu.

Uninzi lwezinto ezingcolisayo kunye nezinto ezixutywayo ziya kwandisa ukugqwala kwentsimbi kwi-zinc bath. Indlela yokugqwala kwentsimbi kwi-zinc bath yahluke ngokupheleleyo kwentsimbi emoyeni okanye emanzini. Ezinye iintsimbi ezinokumelana nokugqwala okuhle kunye nokumelana ne-oxidation, ezifana nentsimbi engagqwaliyo kunye nentsimbi engatshiyo, zinokumelana nokugqwala okuphantsi kwi-zinc enyibilikisiweyo kunentsimbi ye-silicon ephantsi enekhabhoni ephantsi enobumsulwa obuphezulu. Ke ngoko, intsimbi ye-silicon ephantsi enekhabhoni ephantsi enobumsulwa obuphezulu idla ngokusetyenziswa ukwenza iimbiza ze-zinc. Ukongeza inani elincinci lekhabhoni kunye ne-manganese () kwintsimbi akunampembelelo ingako ekumelaneni nokugqwala kwentsimbi kwi-zinc enyibilikisiweyo, kodwa kunokuphucula amandla entsimbi.

Ukusetyenziswa kwembiza ye-zinc

- 1. Ukugcinwa kwembiza ye-zinc

Umphezulu wembiza ye-zinc ebolileyo okanye ebolileyo uya kuba rhabaxa, nto leyo eya kubangela ukubola okukhulu kwe-zinc engamanzi. Ke ngoko, ukuba imbiza entsha ye-zinc kufuneka igcinwe ixesha elide ngaphambi kokuba isetyenziswe, kufuneka kuthathwe amanyathelo okukhusela ukubola, kuquka ukukhuselwa kokupeyinta, ukuyibeka kwindawo yokusebenzela okanye yokugquma ukuze kuthintelwe imvula, ukugquma ezantsi ukuze kuthintelwe ukuntywiliselwa emanzini, njl. Akukho meko apho umphunga wamanzi okanye amanzi aqokelelana khona kwimbiza ye-zinc.

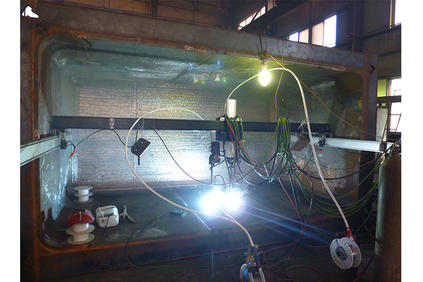

2. Ukufakelwa kwembiza ye-zinc

Xa ufaka imbiza ye-zinc, kufuneka ifuduselwe kwisithando se-zinc ngokweemfuno zomenzi. Ngaphambi kokuba usebenzise ibhoyila entsha, qiniseka ukuba uyayisusa i-rust, i-residual welding slag spatter kunye nolunye uthuli kunye ne-corrosive eludongeni lwebhoyila. I-rust mayisuswe ngendlela yoomatshini, kodwa umphezulu wembiza ye-zinc akufuneki wonakaliswe okanye ube rhabaxa. Ibrashi eqinileyo yefayibha ingasetyenziselwa ukucoca.

Imbiza ye-zinc iya kwanda xa ishushu, ngoko ke kufuneka kubekho indawo yokwanda ngokukhululekileyo. Ukongeza, xa imbiza ye-zinc ikwiqondo lobushushu eliphezulu ixesha elide, kuya kubakho "ukukrwela". Ke ngoko, kufuneka kwamkelwe isakhiwo esifanelekileyo sokuxhasa imbiza ye-zinc ngexesha loyilo ukuze ithintelwe ukuba ingaguquguquki kancinci ngexesha lokusetyenziswa.