Isityalo sokujika isitshixo sisebenza ngeenkqubo ezintathu eziphambili. Ezi nkqubo zisebenza ukulungiselela, ukugquma, kunye nokugqiba intsimbi. Le nkqubo isebenzisa izixhobo ezikhethekileyo ezifanaIzixhobo Zokugquma Isinyithi Kwicandelo LesakhiwokwayeIinxalenye ezincinci zeGalvanizing imigca (Robort)Imarike yokugaya eshushu ibonisa ukukhula okukhulu.

| Icandelo leMarike | Unyaka | Ubungakanani beMarike (iibhiliyoni zeedola) | Unyaka oqikelelweyo | Ubungakanani beMarike obuqikelelweyo (iibhiliyoni zeedola) |

|---|---|---|---|---|

| I-Galvanizing efakwe kwi-Hot-Dipped | 2024 | 88.6 | 2034 | 155.7 |

Izinto ezibalulekileyo ekufuneka ziqwalaselwe

- Isityalo sokufaka i-galvanizing sineenkqubo ezintathu eziphambili: ukucoca kwangaphambili, ukufaka i-galvanizing, kunye nokulungisa emva kokucoca. Ezi nkqubo zisebenza kunye ukucoca, ukugquma, kunye nokugqiba intsimbi.

- Inkqubo yangaphambi konyango ihlambulula intsimbi. Isusa ukungcola, amafutha kunye nomhlwa. Eli nyathelo linceda i-zinc ukuba inamathele kakuhle kwintsimbi.

- Iinkqubo yokugaya i-galvanizingibeka i-zinc coating kwintsimbi. Inkqubo emva konyango iyayipholisa intsimbi kwaye yongeze umaleko wokugqibela wokukhusela. Oku kwenza intsimbi ibe yomelele kwaye ihlale ixesha elide.

Inkqubo 1: Inkqubo yangaphambi koNyango

Inkqubo yangaphambi koNyango lelona nqanaba libalulekileyo nelibalulekileyoinkqubo yokwenza i-galvanizingUmsebenzi wayo ophambili kukulungisa umphezulu wentsimbi ococekileyo ngokugqibeleleyo. Umphezulu ococekileyo uvumela i-zinc ukuba yenze ikhonkco eliqinileyo nelilinganayo nentsimbi. Le nkqubo isebenzisa uthotho lweekhemikhali zokudibanisa ukususa zonke izinto ezingcolisayo.

IiTanki Zokususa Amafutha

Ukususa amafutha linyathelo lokuqala lokucoca. Iindawo zentsimbi zifika kwisityalo ezineengcolisi ezingaphezulu ezifana neoyile, ukungcola, kunye namafutha. Ukususa amafutha kwiitanki kususa ezi zinto. Ezi tanki zinezisombululo zeekhemikhali eziqhekeza ukungcola. Izisombululo eziqhelekileyo ziquka:

- Izisombululo zokususa amafutha kwi-alkaline

- Izisombululo zokususa amafutha nge-asidi

- Izihluzi ze-alkaline ezishushu kakhulu

EMantla Melika, ii-galvanizers ezininzi zisebenzisa izisombululo ze-sodium hydroxide ezishushu. Abaqhubi badla ngokufudumeza ezi tanki ze-alkaline ukuya phakathi kwama-80-85 °C (176-185 °F). Olu bushushu luphucula ukusebenza kakuhle kokucoca ngaphandle kweendleko eziphezulu zamandla zokubilisa amanzi.

Iitanki zokuhlamba

Emva konyango ngalunye lweekhemikhali, intsimbi iya kwitanki yokuhlamba. Ukuhlamba kuhlamba naziphi na iikhemikhali eziseleyo kwitanki yangaphambili. Eli nyathelo lithintela ukungcola kokuhlamba okulandelayo ngokulandelelana. Ukuhlamba ngokufanelekileyo kubalulekile ukuze kugqitywe kakuhle.

Umgangatho woShishino:Ngokwe-SSPC-SP 8 Pickling Standard, amanzi okuhlamba kufuneka acoceke. Isixa esipheleleyo se-asidi okanye iityuwa ezinyibilikisiweyo ezithuthwa zisiwe kwiitanki zokuhlamba akufuneki zidlule iigram ezimbini ngelitha.

Iitanki zokuCoca i-Acid

Okulandelayo, intsimbi ifakwa kwitanki yokucola iasidi. Le tanki inesisombululo seasidi exutyiweyo, ngokuqhelekileyo i-hydrochloric acid. Umsebenzi weasidi kukususa umhlwa kunye nesikali sokugaya, eziyi-iron oxides kumphezulu wentsimbi. Inkqubo yokucola ityhila intsimbi engenanto, ecocekileyo engaphantsi, iyenza ilungele inyathelo lokugqibela lokulungiselela.

IiTanki zokuFluxing

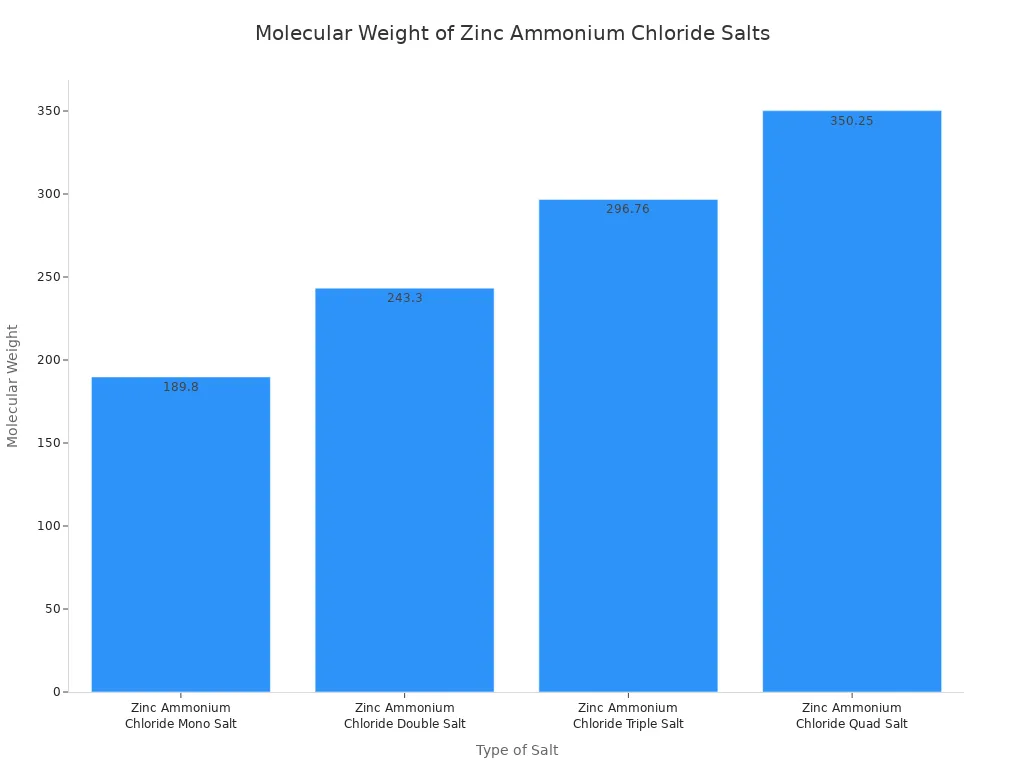

Ukucoca nge-flux linyathelo lokugqibela ngaphambi konyango. Intsimbi ecocekileyo ingena kwi-aitanki yokuhambisa amanziequlethe isisombululo se-zinc ammonium chloride. Esi sisombululo sifaka umaleko okhuselayo wekristale kwintsimbi. Le maleko yenza izinto ezimbini: yenza ukucoca okuncinci kokugqibela kwaye ikhusela intsimbi kwioksijini emoyeni. Le filimu ikhuselayo ithintela ukugqwala okutsha ngaphambi kokuba intsimbi ingene kwi-zinc kettle eshushu.

Umthombo womfanekiso:statics.mylandingpages.co Inkqubo 2: Inkqubo Yokugalela I-Galvanizing

Emva konyango lwangaphambi konyango, intsimbi itshintshelwa kwiNkqubo yeGalvanizing. Injongo yale nkqubo kukusebenzisaugqubuthelo lwezinki olukhuselayoIqulethe izinto ezintathu eziphambili: i-oven yokomisa, i-galvanizing furnace, kunye ne-zinc kettle. Ezi ndawo zisebenza kunye ukudala unxibelelwano lwe-metallurgical phakathi kwentsimbi kunye ne-zinc.

I-oven yokomisa

I-oven yokomisa yeyona ndawo yokuqala kule nkqubo. Umsebenzi wayo ophambili kukomisa intsimbi ngokupheleleyo emva kwesigaba sokujika. Abaqhubi badla ngokufudumeza i-oven ukuya kuma-200°C (392°F). Olu bushushu buphezulu bukhupha yonke intsalela yomswakama. Inkqubo yokomisa ecokisekileyo ibalulekile kuba ithintela ukuqhuma komphunga kwi-zinc eshushu kwaye ithintela iziphene zokugquma ezifana nemingxuma ye-pin.

Ii-oveni zokomisa zanamhlanje zineendlela zokonga umbane. Ezi mpawu zinciphisa ukusetyenziswa kwepetroli kwaye ziphucula ukusebenza kakuhle kwezityalo.

- Bangasebenzisa iigesi zokukhupha umoya ezivela kwisithando somlilo ukuze bafudumale intsimbi kwangaphambili.

- Zihlala ziquka iinkqubo zokubuyisela ubushushu.

- Ziqinisekisa ukusasazwa kobushushu okucwangcisiweyo nokulinganayo.

Isithando somlilo seGalvanizing

Isithando somlilo esibizwa ngokuba yi-galvanizing sibonelela ngobushushu obukhulu obufunekayo ukuze kunyibilikiswe i-zinc. Ezi yunithi zinamandla zijikeleze i-zinc kettle kwaye zigcina i-zinc enyibilikisiweyo kubushushu obuchanekileyo. Izithando zisebenzisa ubuchwepheshe obuphambili bokufudumeza ukuze zisebenze ngokufanelekileyo. Iindidi eziqhelekileyo ziquka:

- Izitshisi Ezishushu Ezisebenzisa Isantya Esiphezulu

- Izitofu zokufudumeza ezingathanga ngqo

- Izithando zombane

Ukhuseleko Kuqala: Izithando zisebenza kumaqondo obushushu aphezulu kakhulu, nto leyo eyenza ukhuseleko lube yinto ebalulekileyo. Zakhiwe nge-insulation enobushushu obuphezulu, ii-sensors zedijithali zokujonga ubushushu bekettle, kunye noyilo oluvumela ukuhlolwa lula kwezitshisi kunye neevalvu zokulawula.

Ikettle yeZinc

Iketile ye-zinc sisikhongozeli esikhulu, esinxande esibamba i-zinc enyibilikisiweyo. Ihlala ngqo ngaphakathi kwesithando somlilo esitshisayo, esisifudumezayo. Iketile kufuneka ihlale ixesha elide kakhulu ukuze imelane namaqondo obushushu aphezulu ahlala ehleli kunye nendalo yokutsha kwe-zinc engamanzi. Ngenxa yesi sizathu, abavelisi bakha iiketile ngentsimbi ekhethekileyo, enekhabhoni ephantsi, nengenasilicon. Ezinye zinokuba nomgca wangaphakathi wezitena ezinganyangekiyo ukuze zihlale ixesha elide.

Inkqubo 3: Inkqubo Yasemva Konyango

Inkqubo yasemva koNyango linqanaba lokugqibelainkqubo yokwenza i-galvanizingInjongo yayo kukupholisa intsimbi esandula ukugqunywa kunye nokufaka umaleko wokugqibela wokukhusela. Le nkqubo iqinisekisa ukuba imveliso inembonakalo efunekayo kwaye ihlala ixesha elide. Izinto eziphambili ziitanki zokucima kunye nezikhululo zokudlulisa umoya.

Iitanki Zokucima

Emva kokuphuma kwiketile ye-zinc, intsimbi isashushu kakhulu, malunga ne-450°C (840°F). Ukucima iitanki kuyayipholisa intsimbi ngokukhawuleza. Oku kupholisa ngokukhawuleza kuyayimisa impendulo ye-metallurgical phakathi kwe-zinc kunye ne-iron. Ukuba intsimbi iphola kancinci emoyeni, le mpendulo ingaqhubeka, ibangele ukugqitywa okufipheleyo, okunamabala. Ukucima kunceda ukugcina inkangeleko ekhanyayo nefanayo. Nangona kunjalo, ezinye iindlela zentsimbi azifanelekanga ukucima kuba utshintsho olukhawulezileyo lobushushu lunokubangela ukugoba.

Abaqhubi basebenzisa izinto ezahlukeneyo zolwelo, okanye iindlela zokucima, ngokusekelwe kwisiphumo esifunekayo:

- Amanzi:Ibonelela ngokupholisa okukhawulezayo kodwa inokwenza iityuwa ze-zinc ezisuswayo phezu komhlaba.

- Iioyile:Pholisa intsimbi kancinci kunamanzi, nto leyo enciphisa umngcipheko wokuqhekeka ngelixa iphucula ukuqina kwayo.

- Iityuwa ezinyibilikisiweyo:Ibonelela ngesantya sokupholisa esicothayo nesilawulwa ngakumbi, nto leyo enciphisa ukugqwetheka.

Ukunyamezela kunye nokugqiba

Unyango lokugqibela lweekhemikhali yi-passivation. Le nkqubo isebenzisa umaleko omncinci, ongabonakaliyo kumphezulu we-galvanized. Le maleko ikhusela i-zinc coating entsha kwi-oxidation yangaphambi kwexesha kunye nokwenziwa "kwe-white rust" ngexesha lokugcina nokuthuthwa.

Inqaku loKhuseleko kunye nokusingqongileyo:Ngokwembali, i-passivation yayidla ngokusebenzisa ii-arhente eziqulethe i-hexavalent chromium (Cr6). Nangona kunjalo, le khemikhali inobungozi kwaye ibangela umhlaza. Amaqumrhu karhulumente afana ne-US Occupational Safety and Health Administration (OSHA) alawula ngokungqongqo ukusetyenziswa kwayo. Ngenxa yezi nkxalabo zempilo nokusingqongileyo, eli shishini ngoku lisebenzisa kakhulu ezinye iindlela ezikhuselekileyo, ezifana ne-trivalent chromium (Cr3+) kunye ne-chromium-free passivators.

Eli nyathelo lokugqibela liqinisekisaimveliso eyenziwe ngesinyithiifika kwindawo eya kuyo icocekile, ikhuselekile, kwaye ilungele ukusetyenziswa.

Iinkqubo zeNkxaso eziBalulekileyo zeZityalo eziBanzi

Iinkqubo ezintathu eziphambili kwisityalo esisebenzisa i-galvanizing zixhomekeke kwiinkqubo zenkxaso ezibalulekileyo ukuze zisebenze ngokukhuselekileyo nangokufanelekileyo. Ezi nkqubo zisebenza kwisityalo sonke zijongana nokuhamba kwezinto, imisebenzi ekhethekileyo yokugquma, kunye nokhuseleko lokusingqongileyo. Zidibanisa yonke inkqubo ukususela ekuqaleni ukuya ekupheleni.

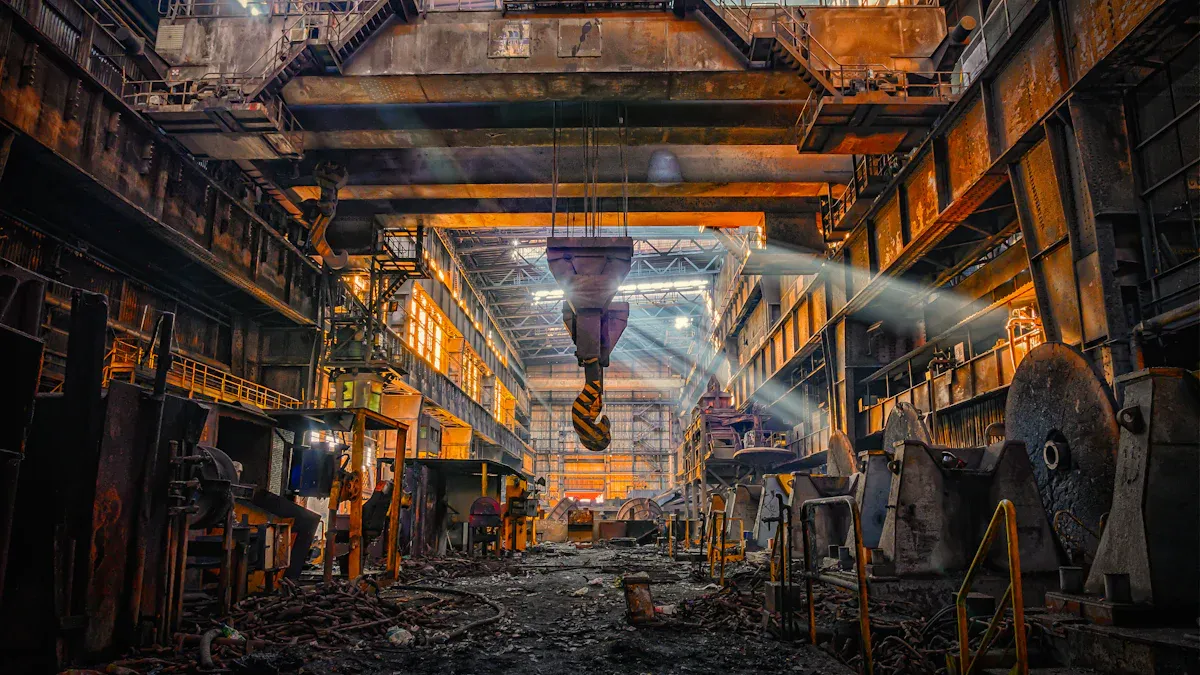

Inkqubo yokuphatha izinto

Inkqubo yokuphatha izinto ihambisa izinto ezenziwe ngentsimbi enzima kulo lonke iqumrhu. Izityalo zanamhlanje zokugaya iigesi zifuna iikhreyini zodidi oluphezulu kunye nezinye izixhobo ukulawula umsebenzi. Ezi zixhobo kufuneka ziphathe ubunzima bezinto kwaye zimelane nobushushu obuphezulu kunye nokuvezwa ziikhemikhali.

- Iikhreyini

- IiHoist

- IiConveyors

- Abaphakamisi

Abaqhubi kufuneka baqwalasele umthamo omkhulu womthwalo wale zixhobo. Kwizinto ezenziwe ngobuninzi kakhulu, kungcono ukubonisana ne-galvanizer ukuqinisekisa ukuba inkqubo yabo iyakwazi ukumelana nobunzima. Olu cwangciso luthintela ukulibaziseka kwaye luqinisekisa ukuphathwa ngokukhuselekileyo.

Izixhobo Zokugquma Isinyithi Kwicandelo Lesakhiwo

Ukusetyenziswa kwezityaloIzixhobo Zokugquma Isinyithi Kwicandelo Lesakhiwoukuze kufunyanwe i-zinc coating efanayo kwizinto ezinkulu okanye ezintsonkothileyo. Ukuntywila okuqhelekileyo kusenokunganeli kwiziqwenga ezineemilo ezingaqhelekanga okanye umphezulu wangaphakathi. Esi sixhobo sikhethekileyo sisebenzisa iindlela eziphambili, ezifana nokuhamba kwenxalenye elawulwayo okanye iinkqubo zokutshiza ezenzekelayo, ukuqinisekisa ukuba i-zinc enyibilikisiweyo ifikelela kumphezulu ngamnye ngokulinganayo. Ukusebenzisa izixhobo ezifanelekileyo ze-Structural Component Galvanizing Equipment kubalulekile ekuhlangabezaneni nemigangatho yomgangatho kwizinto ezifana neebhanti ezinkulu okanye iindibano ezintsonkothileyo. Ukusetyenziswa ngokufanelekileyo kwe-Structural Component Galvanizing Equipment kuqinisekisa ukugqitywa okuzinzileyo nokukhuselayo.

Ukukhupha noNyango lweFutha

Inkqubo yokugaya igesi idala umsi, ingakumbi kwiitanki zokucoca iasidi kunyeiketile eshushu ye-zincInkqubo yokukhupha nokucoca umsi ibalulekile kukhuseleko lwabasebenzi kunye nokukhuselwa kwendalo. Le nkqubo ibamba umphunga onobungozi kumthombo wawo, icoce umoya ngee-scrubbers okanye izihluzi, ize emva koko iwukhuphe ngokukhuselekileyo.

Ukhuseleko kunye nokusingqongileyo:Ukukhupha umsi ngokufanelekileyo kukhusela abasebenzi ekuphefumleni umphunga weekhemikhali kwaye kuthintela ukukhutshwa kokungcola emoyeni, kuqinisekisa ukuba isityalo sithobela imithetho yokusingqongileyo.

Isityalo sokugalela intsimbi esijika-jika sidibanisa iinkqubo ezintathu eziphambili. Ngaphambi konyango sicoca intsimbi ukuze inamathele kwi-zinc. Inkqubo yokugalela intsimbi isebenzisa ugqubuthelo, kwaye emva konyango igqiba imveliso. Iinkqubo zenkxaso, kuquka nezixhobo zokugalela intsimbi kwiSakhiwo, zidibanisa yonke inkqubo. Izityalo zanamhlanje zisebenzisa oomatshini kunye neempawu zokusebenza eziphambili ukuphucula ukusebenza kakuhle kunye nokuzinza.

Ixesha lokuthumela: Novemba-03-2025