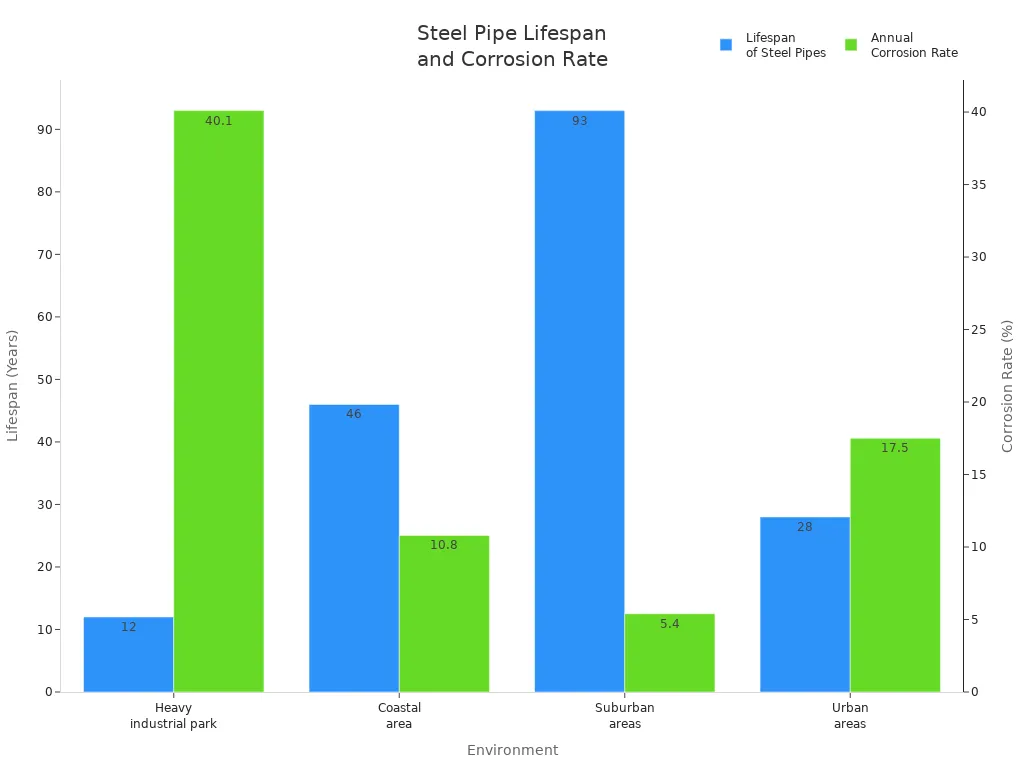

Ukhusela imibhobho yentsimbi kwi-rust ngokusebenzisa i-hot-dip galvanizing.Izixhobo zokugaya i-hot-dip ngepayipi yentsimbiigubungela umbhobho ngamnye nge-zinc, nto leyo eyenza ikhaka lokulwa nokugqwala.Iipayipi Imigca yokugaya isinyithinceda ukuqinisekisa ukuba isiphelo sayo siqinile, silingana. Jonga itshathi engasezantsi. Ibonisa indlela imibhobho ye-galvanized ehlala ngayo ixesha elide kwiindawo ezahlukeneyo.

Izinto ezibalulekileyo ekufuneka ziqwalaselwe

- I-hot-dip galvanizingikhusela imibhobho yentsimbi kumhlwa ngokufaka i-zinc coating etyebileyo, esebenza njengomqobo wokungagqwali.

- Ukulungiswa komphezulu ngendlela efanelekileyoKubalulekile. Ukucoca nokuqhola imibhobho kuqinisekisa ukuba i-zinc inamathela kakuhle, nto leyo ethintela iziphene kwi-coating.

- Iipayipi ze-galvanized zinika ukuqina okuhlala ixesha elide, zihlala iminyaka engama-40 ukuya kwengama-50, nto leyo eyenza ukuba zibe lukhetho olungabizi kakhulu kumashishini ahlukeneyo.

Izixhobo zeSteel Pipe Hot-Dip Galvanizing kunye namanyathelo eNkqubo

Umbhobho wentsimbiizixhobo zokugaya nge-hot-dipIkunceda ukhusele imibhobho yentsimbi kumhlwa nasemngciphekweni. Usebenzisa ezi zixhobo kumashishini amaninzi, afana nokwakha, oomatshini, izityalo zeekhemikhali, kunye noololiwe. Ezi zixhobo ziphatha imibhobho enobubanzi obuphakathi kwe-1/2 ukuya kwi-10 intshi kunye nobude obuphakathi kwe-4 ukuya kwi-8 yeemitha. Ingagquma imibhobho nge-zinc enobunzima obuphakathi kwe-50 kunye ne-400 grams ngemitha yesikwere. Ezi zixhobo zinokucubungula ukuya kuthi ga kwiitoni ezingama-80,000 zemibhobho yentsimbi minyaka le.

| Into | Inkcazo |

|---|---|

| izinto | ucingo lwentsimbi |

| uluhlu lobubanzi | 1/2 ~10 intshi |

| uluhlu lobude bepayipi | 4~8 m |

| uhlobo lokwaleka | izinki |

| ubunzima bokugquma | 50~400g/m2 |

| umthamo | 40000~80000T/ngonyaka |

Ukulungiswa Nokucoca Umphezulu

Uqala ngokucoca imibhobho yentsimbi. Eli nyathelo lisusa ukungcola, ioyile, kunye nezinye izinto ezingcolisayo. Ukuba awuzicoci, i-zinc coating ayizukunamathela kakuhle. Kufuneka ususe i-weld slag, ii-burrs, i-mill scale, ii-varnishes, ii-epoxies, isanti, iipeyinti ezisekwe kwioyile, iimpawu zekhrayoni, kunye ne-wax etyebileyo okanye igrisi. Usebenzisa iibhafu zokususa amafutha kunye ne-sodium hydroxide ukususa iioyile kunye negrisi. Emva kokususa amafutha, uhlamba imibhobho ngamanzi. Emva koko usebenzisa i-hydrochloric okanye i-sulfuric acid ukususa umhlwa kunye ne-mill scale. Eli nyathelo libizwa ngokuba yi-pickling.

Icebiso: Soloko uhlamba imibhobho emva kokucoca i-asidi ukuze ususe zonke iintsalela ze-asidi. Yomisa imibhobho ngokupheleleyo ngaphambi kokuba uye kwinqanaba elilandelayo.

Ukucoca iipayipi zentsimbi

Okulandelayo, ufaka imibhobho kwisisombululo se-flux. I-Fluxing isusa naziphi na ii-oxides eziseleyo kwaye ithintele i-oxidation entsha ngaphambi kokuba ugqume imibhobho nge-zinc. Usebenzisa isisombululo se-zinc ammonium chloride kweli nyathelo. Ubushushu obufanelekileyo bokuqubha buphakathi kwama-60 nama-80 °C. Olu bushushu lunceda i-flux ukucoca kakuhle umphezulu wentsimbi. Iiarhente eziphambili zokuqubha yi-zinc chloride kunye ne-ammonium chloride. Ezi khemikhali zisusa i-iron oxide kwaye ziphucule ukuhamba kwe-zinc. I-Fluxing ikwanceda ukuba usebenzise i-zinc encinci kwaye inciphise inkunkuma.

- I-Zinc chloride: 60–80%

- I-Ammonium chloride: 7–20%

- Izinto zokuguqula ulwelo: 2–20%

- Ezinye izinto ezidityanisiweyo: i-nickel, i-cobalt, i-manganese, i-lead, i-tin, i-bismuth, i-antimony

Ukuntywiliselwa kwiBath yeZinc

Emva koko untywilisela imibhobho kwibhafu ye-zinc enyibilikisiweyo. Izixhobo ze-steel pipe hot-dip galvanizing zigcina ibhafu ye-zinc kubushushu obufanelekileyo, ngesiqhelo phakathi kwama-825 nama-870 °F (440–460 °C). Ugcina imibhobho ebhafini imizuzu emi-5 ukuya kweli-15. Ngeli xesha uvumela i-zinc ukuba inamathele kwintsimbi kwaye yenze uqweqwe oluqinileyo nolulinganayo. Ibhafu ye-zinc igubungela yonke indawo yombhobho, nokuba ngaphakathi nangaphandle kwee-welds.

Qaphela: Ukuba awulawuli ubushushu okanye ixesha, unokufumana iziphene ezifana namaqhuqhuva, amadyungudyungu, okanye ukuxobuka.

Ukupholisa kunye nokucoca kokugqibela

Emva kokuba ukhuphe imibhobho kwindawo yokuhlamba i-zinc, uyayipholisa kwi-quench tank. Ukupholisa kuyayithintela i-reaction phakathi kwe-zinc nomoya. Emva koko uhlamba imibhobho ngamanzi amatsha ukususa naziphi na iikhemikhali eziseleyo. Ukuba usebenzise ukucoca nge-asidi, hlambulula imibhobho okwesibini. Yomisa imibhobho ngomoya oshushu ukuqinisekisa ukuba akukho kufuma okushiyekileyo. Eli nyathelo ligcina umphezulu ucocekile kwaye lithintela umhlwa omhlophe.

- Hlamba ngamanzi amatsha

- Yomisa ngomoya oshushu

- Gcina imibhobho kwindawo eyomileyo

Uvavanyo kunye noVavanyo loMgangatho

Kufuneka uhlole imibhobho ukuqinisekisa ukuba i-coating iqinile kwaye ilingana. Usebenzisa ukujonga okubonakalayo, ukulinganisa ubukhulu, kunye novavanyo lokufana. Ukwajonga uburhabaxa, ukugqwala, kunye nomonakalo. Ulinganisa ubungakanani bombhobho kwaye ujonge ukuvuza. Ulandela imigangatho efana ne-ASTM A500 kunye ne-EN 10219. Le migangatho ikunceda uqinisekise ukuba imibhobho iya kuhlala ixesha elide kwaye iyamelana nokugqwala.

Indlela yokuhlola Inkcazo Uhlolo olubonakalayo Jonga ukuba zithambile, azinaziphene, kwaye azinamhlwa Ubukhulu beseleko Sebenzisa iimitha ukulinganisa ubukhulu bengubo Ukufana Khangela ukuxobuka okanye uqweqwe olungalinganiyo Uburhabaxa Uvavanyo loburhabaxa bomphezulu Ukuhlolwa kokugqwala Fumana imikrwelo okanye umonakalo Umgangatho wokuwelda Jonga ukuba akukho mifantu okanye inkunkuma Ukwakheka kweekhemikhali Vavanya ubungakanani obuchanekileyo bezinki kunye nentsimbi Ukuziphatha koomatshini Linganisa amandla kunye nokuguquguquka Uvavanyo lobukhulu Qinisekisa ububanzi, ubukhulu, kunye nobude Ilogo kunye nokumakishwa Jonga iilebheli ezichanekileyo Uvavanyo lokuvuza Qinisekisa ukuba imibhobho ayinamingxunya okanye imingxunya Isikhumbuzo soKhuseleko: Soloko ulandela imithetho yokhuseleko xa usebenzisa izixhobo zentsimbi zokugalela isinyithi esishushu. Hlola imibhobho ukuze ubone umonakalo kwaye uqinisekise ukuba umgangatho wamanzi ulungile ukuze uthintele ukugqwala.

Iingenelo zeSixhobo seGalvanizing sePipe yeNtsimbi

Ukhuseleko oluphezulu lweRust kunye neCorrosion

Ufumana ukhuseleko oluqinileyo kumhlwa xa usebenzisaizixhobo zokugaya i-galvanizing zombhobho wentsimbi. Ingubo ye-zinc yenza umqobo ongqindilili ogcina amanzi, umoya, kunye neekhemikhali kude nentsimbi. Lo mqobo usebenza ngcono kunepeyinti okanye iingubo ezincinci. I-zinc ikwakhusela intsimbi ukuba ingubo iyakrweleka. I-zinc iya kuqala ibole, igcine intsimbi engaphantsi.

- Umaleko we-zinc otyebileyo uyamelana nemozulu embi kunye neekhemikhali.

- Uyayibona le ndlela isetyenziswa kwiibhulorho, kwiireyili, nakwiipayipi zangaphandle kuba ihlala ixesha elide.

- Ingubo ye-zinc isebenzisa zombini izithintelo kunye nokhuseleko lokuzincama, ngoko ke imibhobho yakho ihlala ikhuselekile nokuba umphezulu wonakele.

Izifundo zesayensi zibonisa ukuba i-zinc yenza iikhompawundi ezikhethekileyo, ezifana ne-ZnO kunye ne-Zn5Cl2(OH)8, ezicothisa umhlwa kwaye zigcine imibhobho yomelele kwiindawo ezinzima.

Indlela yokusebenza Inkcazo Ukhuseleko lweMiqobo Umaleko weZinc uvimba amanzi nomoya ukuba ungafikeleli kwintsimbi. Ukukhuselwa Ngumbingelelo I-Zinc iyagqwala ngaphambi kwentsimbi, iyikhusela nokuba ikrwelwe. Imozulu yendalo Ekuhambeni kwexesha, i-zinc yenza iileya ezongezelelweyo ezongeza ukhuseleko olungakumbi. Ukuqina Okuphuculweyo kunye Nokuphila Ixesha Elide

Ungalindela ukuba imibhobho ye-galvanized ihlale amashumi eminyaka. Okukhona i-zinc coating ityebile, kokukhona imibhobho yakho iya kuhlala ixesha elide. Umzekelo:

Uhlobo lokwaleka Ixesha Elilindelekileyo Lokuphila Kwiindawo Eziphakathi G30 Iminyaka emi-5–10 G90 Iminyaka engama-20 nangaphezulu Uninzi lweepayipi ze-galvanizing zihlala iminyaka engama-40 ukuya kwengama-50. Kwiindawo ezomileyo, zinokuhlala ixesha elide nangakumbi. Ukuba usebenzisa izixhobo ze-galvanizing zepayipi yentsimbi, unceda iipayipi zakho ukuba zingabi nagqwala kwaye zonakaliswe iminyaka emininzi.

- Iipayipi kwiindawo ezinomswakama omncinci zinokuhlala iminyaka engama-70.

- Kwiindawo ezimanzi okanye ezinetyuwa, ubomi bomzimba bunokuba bufutshane, kodwa bube bude kakhulu kunentsimbi engagqunywanga.

UkuSebenza kakuhle kweendleko kunye nokugcinwa okuphantsi

Ugcina imali ngokuhamba kwexesha ngeepayipi ze-galvanized. Ixabiso lokuqala liphezulu kancinci kunepeyinti, kodwa uchitha imali encinci ekulungiseni nasekulungiseni. Nantsi intelekelelo ekhawulezileyo:

Indlela yoKhuselo Ixabiso lokuqala Ulindelo lobomi (iminyaka) Iindleko zoLondolozo I-NPV Ukuntywila okushushu 100 25 0 100 Inkqubo yokupeyinta 90 8 169 169 Iipayipi ze-galvanized azidingi kucocwa kakhulu kwaye azidingi kulungiseka kakhulu. Ukwaleka kwazo okuqinileyo kuthetha ukuba akufuneki ukhathazeke ngokugqwala okanye ukuvuza rhoqo. Oku kuzenza zibe lukhetho olukrelekrele kwiiprojekthi ezinkulu nakwiindawo apho ufuna iipayipi zihlale ixesha elide khona.

Izixhobo zokufaka i-galvanizing ezishushu zikunceda ukhusele iipayipi zentsimbi iminyaka emininzi. Ufumana ukusebenza okuthembekileyo kwiindawo ezahlukeneyo.

- Ukuqina kwexesha elide kuxhomekeke kwiimeko zendalo.

- Iingcali zithiInyathelo ngalinye lenkqubo lichaphazelaumgangatho kunye namandla okugquma.

Inyathelo Impembelelo kwiNzuzo esebenzayo Ukucoca Iphucula ukunamathela kwaye ithintele iimpazamo Ukukha Ichaphazela ukugudileyo kunye nomgangatho Ukufudumeza Iqinisekisa ukuhamba kwe-zinc ngokulinganayo Ukuntywiliselwa Ulawulo lobukhulu kunye nomgangatho wangaphakathi Uhlolo Iqinisekisa ukuba upende uyahlangabezana nemigangatho

Ixesha leposi: Sep-11-2025