Ufuna izixhobo ezihlala ixesha elide. Izikrufu ze-galvanized kunye neenati zihlala ixesha elide kunezinye izinto ezifakwe i-zinc, ingakumbi ngaphandle. Jonga nje amanani angezantsi:

| Uhlobo lweSikrufu/iNut | Ixesha Lokuphila Kwizicelo Zangaphandle |

|---|---|

| Izikrufu/Amantongomane agqunyiweyo | Iminyaka engama-20 ukuya kwengama-50 (yasemaphandleni), iminyaka eli-10 ukuya kwengama-20 (yemizi-mveliso/yonxweme) |

| Izikrufu ezineZinc-Plated | Iinyanga ezimbalwa ukuya kwiminyaka emi-2 (imozulu eyomileyo), ngaphantsi konyaka omnye (enomswakama), iinyanga ezimbalwa kuphela (elunxwemeni) |

Ukuba usebenzisa ngokufanelekileyoIzixhobo zokugalela i-screw kunye ne-nut, ufumana ukhuseleko oluthembekileyo.Izixhobo zokugaya isinyithiyenza umahluko ocacileyo ekuqineni.

Izinto ezibalulekileyo ekufuneka ziqwalaselwe

- Izikrufu kunye neenati ezigayiweyoihlala ixesha elide kakhulu kuneenketho ezifakwe i-zinc, nto leyo eyenza ukuba zilungele iiprojekthi zangaphandle.

- Ukwaleka kwezinki kwizixhobo zokubopha ezigayiweyo kunikaukumelana nokugqwala okugqwesileyo, zikhusela kwingqele kwiindawo ezinobungozi.

- Ukukhetha izixhobo ze-galvanized kunokubangela ukonga imali ekuhambeni kwexesha ngenxa yokuncipha kokugcinwa kwazo kunye nokuncipha kokutshintshwa kwazo.

Iingenelo eziphambili zee-Galvanised Screws kunye neeNuts

Ukumelana nokugqwala

Ufuna izikrufu kunye neenati zakho zihlale ixesha elide, ingakumbi kwiindawo ezinzima.Izibophelelo zeGalvanishiine-zinc coating ebakhusela kwi-rust. Olu maleko lusebenza njengekhaka ekufumaneni nakwiikhemikhali. Ungazisebenzisa ezi screws kunye neenati ngaphandle, kwiindawo ezifumileyo, okanye kufutshane nolwandle.

Olu phononongo luhlolisise ukusebenza kokugqwala emoyeni kweebholiti zentsimbi ezigayiweyo kwindawo yaselwandle kangangeminyaka emibini. Lufumanise ukuba uqweqwe lwezinc alunazo ukhuseleko oluphezulu kwisiseko sentsimbi esingaphantsi, kwaye nangona ukwakheka komaleko oxineneyo womhlwa, ukuwohloka kwe-fastener kwakubaluleke kakhulu, nto leyo ebonisa ukuba kunokwenzeka ukuba i-exfoliation iphakame kwaye ingakwazi ukususa intambo.

Intsimbi egayiweyo ayifani nokumelana nokugqwala kwentsimbi engagqwaliyo, kodwa isakhusela ngcono kunentsimbi eqhelekileyo. Ungawubona umahluko kwitheyibhile engasezantsi:

| Izinto eziphathekayo | Ukumelana nokugqwala | Amanqaku |

|---|---|---|

| Intsimbi Egalelweyo | Ingaphantsi kunentsimbi engagqwaliyo; i-zinc coating inokonakala nto leyo ekhokelela kumhlwa | Ukhetho olungabizi kakhulu, kodwa alunamandla kakhulu kwiindawo ezinzima. |

| Yenziwe ngentsimbi eshayinayo | Ukumelana okuphezulu kokugqwala ngenxa yomaleko we-chromium oxide; ukumelana nokuba ukrwelwe | Ibiza kakhulu, kodwa inika ukuqina kwexesha elide kunye nokukhuselwa kokugqwala. |

Ukuhlala ixesha elide

Udinga izixhobo ezihlala ixesha elide.Izikrufu kunye neenati ezigayiweyoZihlala ixesha elide kakhulu kunezo zigqunywe zinc. I-zinc coating izinceda ukuba zikwazi ukumelana neemeko ezimanzi kunye nemozulu embi. Ungathembela kuzo kwiiprojekthi zangaphandle ezifana neengcingo, iibhulorho, kunye needekhi.

- Izikrufu ze-galvanized ezisebenza nzima zinika amandla amangalisayo kunye nokuqina okumangalisayo kwiiprojekthi zangaphandle.

- Ziyindlela engabizi kakhulu kunentsimbi engagqwaliyo, nto leyo eyenza ukuba zibe lukhetho olufanelekileyo kwiintlobo ngeentlobo zezicelo.

- Izikrufu ze-galvanized ziyasebenza kwimisebenzi yangaphandle ngenxa ye-zinc coating yazo, ezinceda ukuba zimelane neemeko ezimanzi kunye nemozulu embi.

- Zibonelela ngonxibelelwano oluqinileyo kwizakhiwo ezifana neengcingo, nto leyo ezenza zibe lukhetho oluhlala ixesha elide kwiindlela zangaphandle.

Ungathelekisa ubomi bezinto ezahlukeneyo zokubopha:

- Izikrufu ezinezinki: iminyaka eli-10-15 ngaphakathi, iminyaka eli-1-3 ngaphandle kwiindawo ezivulekileyo.

- Izikrufu zegalvani ezishushu: Ngaphezulu kweminyaka engama-50 ngaphakathi, iminyaka eli-10-20 ngaphandle, iminyaka emi-5-7 kufutshane nolwandle.

- Izikrufu zentsimbi engagqwali ezingama-304: Ubomi bonke ngaphakathi endlwini, iminyaka engaphezu kwama-30 ngaphandle, iminyaka eli-10-15 kwiindawo zaselwandle.

- Izikrufu zentsimbi engagqwali ezingama-316: Ubomi bazo bonke phantse kuzo zonke iindawo, ngaphezulu kweminyaka engama-25 ecaleni kolwandle.

- Izikrufu zesinyithi ze-silicon bronze: iminyaka engaphezu kwama-50 emanzini anetyuwa.

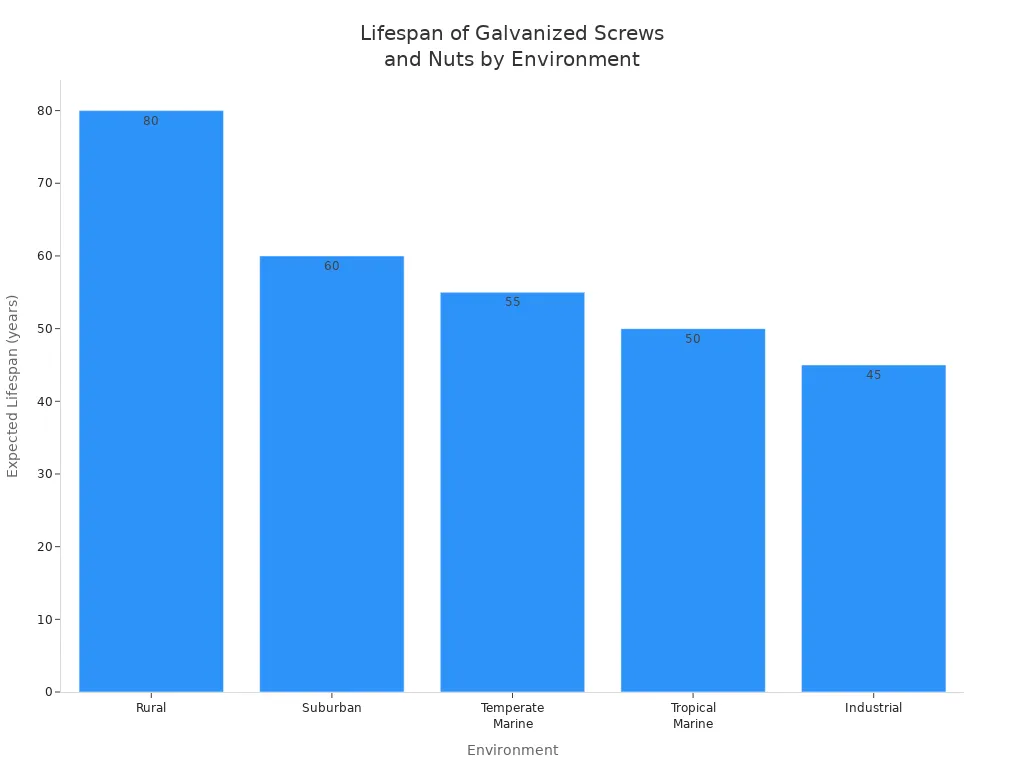

Izikrufu kunye neenati ezifakwe i-galvanized zinokuhlala amashumi eminyaka kwiindawo ezahlukeneyo. Itshathi engasezantsi ibonisa ukuba ungalindela ukuba zihlale ixesha elingakanani:

| Okusingqongileyo | Ixesha Elilindelekileyo Lobomi |

|---|---|

| Yasemaphandleni | Iminyaka engaphezu kwama-80 |

| Idolophu esemazantsi | Iminyaka engama-60 nangaphezulu |

| Ulwandle oluQhelekileyo | Iminyaka engama-55 nangaphezulu |

| Ulwandle lwaseTropiki | iminyaka engaphezu kwama-50 |

| Imizi-mveliso | Iminyaka engama-45 nangaphezulu |

Ukonga Iindleko Ngokuhamba Kwexesha

Wonga imali xa ukhetha izikrufu ze-galvanized kunye neenati. Ezi zibophelelo azidingi ulondolozo oluninzi kwaye azidingi ukutshintshwa kakhulu. Uchitha imali encinci ekulungiseni nasekusebenzeni iminyaka emininzi.

- Iindleko Zokulungisa Ezincitshisiweyo: Intsimbi eyenziwe nge-galvanized ayifuni ukugcinwa kakhulu ubomi bayo bonke, nto leyo ekhokelela ekongeni kakhulu iindleko zokulungisa.

- Ixesha Elide Lobomi: Ixesha elide lobomi bentsimbi egayiweyo linciphisa isidingo sokutshintshwa rhoqo, nto leyo enegalelo ekongeni iindleko.

Ufumana ixabiso elingakumbi ngotyalo-mali lwakho. Izixhobo ezenziwe nge-galvanized zikunceda uphephe iindleko ezingalindelekanga kwaye zigcine iiprojekthi zakho ziqinile kangangeminyaka.

Ukuguquguquka kwiindawo ezahlukeneyo

Ungasebenzisa izikrufu ze-galvanized kunye namandongomane kwiindawo ezininzi. Zisebenza kakuhle ngaphandle, kwiindawo ezimanzi, nakwiindawo ezinemozulu etshintshayo. Ukwaleka kwazo nge-zinc kuzenza zibe lolona khetho luphezulu kwiiprojekthi zokwakha nezangaphandle.

Izikrufu kunye neenati ezigayiweyo zibalasele kwiindawo zangaphandle nezinomswakama ophezulu ngenxa yokuqina kwazo okuphuculweyo kunye nokumelana nokugqwala, nto leyo eyenza ukuba zibe lukhetho olukhethwayo kwiiprojekthi zokwakha nezangaphandle.

Amashishini amaninzi axhomekeke kwizixhobo ze-galvanized kuba zilungelelaniswa neemeko ezahlukeneyo. Ungabona ezinye zeendlela ezisetyenziswa ngazo rhoqo kwitheyibhile engezantsi:

| Ishishini | Inkcazo yesicelo |

|---|---|

| Ulwakhiwo | Isetyenziswa kwiindibano zesakhelo kunye neendlela zenjini, inika ukumelana nokungcangcazela, ubushushu kunye nokufuma. |

| Iimoto | Kubalulekile kwizinto ezahlukeneyo, ukuqinisekisa ukuqina kunye nokusebenza kakuhle kweendleko. |

| Ezolimo | Isetyenziswa ekulungiseni izixhobo kunye noomatshini, ivezwa kumswakama kunye neekhemikhali, nto leyo ephucula ubomi bayo. |

| Imizi-mveliso yoNxweme | Iluncedo ngenxa yengubo ye-zinc ekhusela ukugqwala kwamanzi anetyuwa. |

| Imizi-mveliso | Kubalulekile ukubopha oomatshini, iziseko zesinyithi, kunye neenkqubo ze-HVAC kwiindawo ezirhabaxa. |

Ungathemba izikrufu ze-galvanized kunye neenati ukuba zisebenze kwiindawo ezininzi, ukusuka kwiifama ukuya kwimizi-mveliso ukuya kwizakhiwo ezikunxweme.

Iingxaki eziphambili zeGalvanized Hardware

Umngcipheko wokuqhekeka kweHydrogen

Ufanele ukwazi malungaukuqhekeka kwehydrogenngaphambi kokukhetha izikrufu ze-galvanized kunye neenati. Le ngxaki yenzeka xa i-hydrogen ingena kwisinyithi ize iyenze ibe buthathaka. Isinyithi esibhityileyo sinokuqhekeka okanye siqhekeke phantsi koxinzelelo.

Zininzi izinto ezibangela umngcipheko wokuqhekeka kwe-hydrogen:

- Ukubola, ingakumbi kwiindawo ezine-asidi okanye ezinetyuwa, kuvelisa i-hydrogen kwiindawo zesinyithi.

- Ukufuma kudlala indima enkulu, ingakumbi kwiindawo ezinomswakama ophezulu.

- Ukuvezwa ngexesha lokwakha, njengokusebenza kwiimeko ezimanzi, kunokukhawulezisa ukungena kwe-hydrogen.

- Iimeko zenkonzo ezinamazinga angaqinisekanga okanye aphezulu okufuma zinyusa umngcipheko.

Ujongene nomngcipheko omkhulu xa ezi zinto zintathu zisenzeka kunye:

- I-hydrogen ikhona.

- I-fastener iphantsi komthwalo okanye uxinzelelo oluqhubekayo.

- Le nto ibuthathaka, ingakumbi intsimbi enamandla kakhulu.

Uxinzelelo olungenziwanga ngabom ngexesha lokufakelwa lunokuthwala izikrufu ezininzi kwaye lwenze kube lula ukuba izikrufu zibe buhlungu. Kufuneka usoloko ulawula imithombo yoxinzelelo kwaye uphephe ukuqinisa izibophelelo.

Ingcebiso:Ukuba usebenzisa izibophelelo ze-galvanized kwiindawo ezimanzi okanye ezirhabaxa, jonga iimpawu zokuqhekeka okanye ukulahleka kwamandla ngokuhamba kwexesha.

Imiba Yokuzila Ukuqina Kwe-Zinc Coating

Izikrufu kunye neenati ezigayiweyo zine-zinc coating etyebileyo. Le coating ikhusela kwi-rust, kodwa inokubangela iingxaki xa uzama ukubopha iindawo kunye. Ubukhulu bomaleko we-zinc bunokwenza izikrufu kunye neenati zibe nzima ukungena kwimingxunya okanye kwimisonto.

| Umbono | Iinkcukacha |

|---|---|

| Ubukhulu beZinc CoatingUluhlu | 45–65 μm |

| Impembelelo ekuQokeleni | Iingubo ezityebileyo zifuna ukubethelwa ngaphezulu kwemingxunya ukuze ilingane nezibophelelo, nto leyo echaphazela ukubethelwa okuqinileyo. |

| Ukhuseleko lokugqwala | Ingubo ye-zinc kwimisonto yamadoda ikhusela zombini izinto ekungcoleni nangona zithengwa ngaphezulu. |

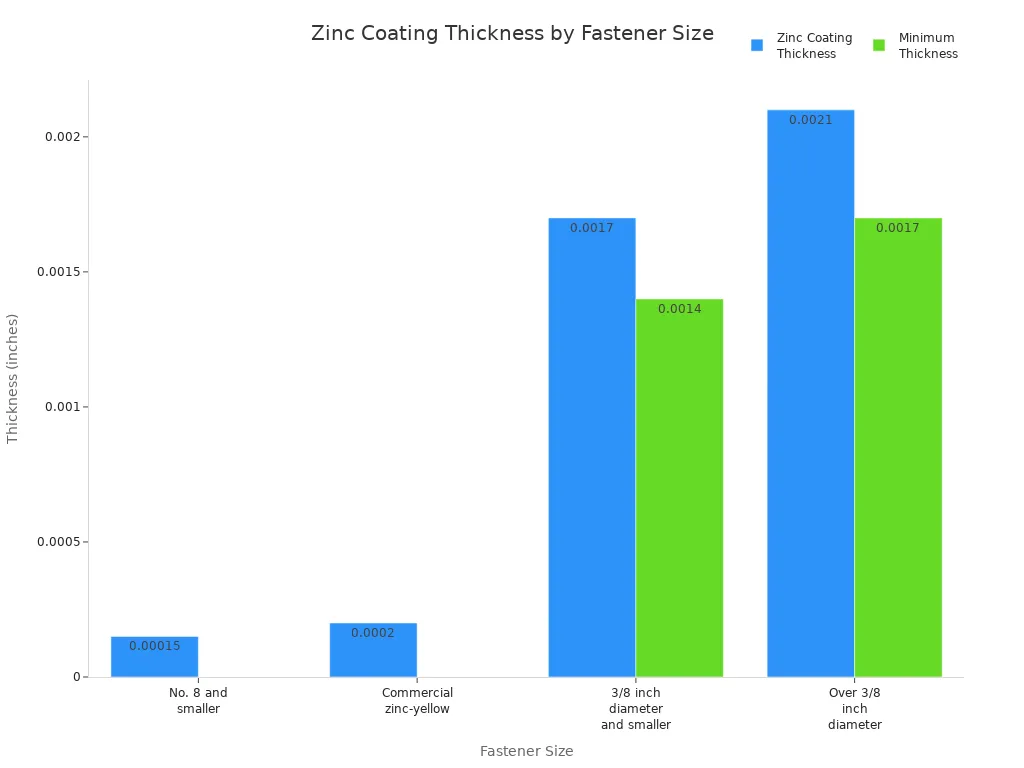

Imigangatho yoshishino ibeka imida yobukhulu be-zinc coating ukuthintela iingxaki zokubopha. I-zinc plating idla ngokunika umaleko omncinci nokhazimlayo, olungele izibophelelo ezincinci kwiimeko ezithambileyo. I-hot-dip galvanizing idala umaleko otyebileyo kakhulu, osebenza ngcono kwiindawo ezinzima kodwa unokwenza ukuba ukubopha kube nzima ngakumbi.

| Ubungakanani beFastener | Ubukhulu beZinc Coating (intshi) | Ubuncinane boBukhulu (ii-intshi) |

|---|---|---|

| Inombolo 8 kwaye incinci | 0.00015 | Ukwambatha okuncinci kwamkelekile |

| I-zinc-tyheli yezorhwebo | 0.00020 | Ukwambatha okuncinci kwamkelekile |

| Ububanzi obuyi-3/8 intshi kwaye buncinci | 0.0017 | 0.0014 |

| Ngaphezulu kwe-3/8 intshi ububanzi | 0.0021 | 0.0017 |

- Iplati ye-zinc yorhwebo inobukhulu obuncinci obuyi-0.00015 intshi.

- I-hot dip galvanizing inika uqweqwe olutyebileyo noluhlala ixesha elide, olunobukhulu obuyi-1.0 mm.

- Izibophelelo ze-zinc ezifakwe kwi-zinc zisebenza kakuhle kwiindawo ezithambileyo, kodwa izibophelelo ze-galvanized ezifakwe kwi-hot-dipped zingcono kwiimeko ezinzima.

Ayilungelanga Ukusetyenziswa Ngoxinzelelo Oluphezulu

Izikrufu kunye neenati ezigayiweyo azisebenzi kakuhle xa zisetyenziswa xa zixinezelekile kakhulu okanye xa zithwala umthwalo. Ungabona iingxaki ezifana nokuqhekeka okanye ukungasebenzi ngequbuliso ukuba uzisebenzisa apho kukho amandla anamandla khona.

Umngcipheko wokuqhekeka kwe-hydrogen uphezulu kwizixhobo zokubopha ezinamandla okutsalwa ngaphezulu kwe-150 ksi. Le ngxaki ibangela ukuba isinyithi silahlekelwe bubuchule kwaye siqhekeke kwangethuba. Imigangatho yoshishino, efana ne-ASTM A143 kunye ne-ASTM F2329, ilumkisa ngokusebenzisa izixhobo zokubopha ezishushu eziditywayo kwimisebenzi enamandla aphezulu.

Kwiindawo ezixinezelekileyo kakhulu, iibholiti ze-galvanized zinokuchaphazeleka kukuqhekeka kokubola okubangelwa yi-hydrogen. Amandla azo anokwehla ngaphezulu kwama-20% emva kokusetyenziswa ixesha elide. Umxholo we-hydrogen kwezi boliti unokwanda ngaphezulu kwama-300%, nto leyo ebangela ukuba zingaphumeleli. Iibholiti ezigqunywe ngamandla aphezulu zigcina iimpawu zazo zoomatshini zingcono xa zixinezelekile.

Phawula:Kwiibhulorho, oomatshini abanzima, okanye izixhaso zesakhiwo, kufuneka ukhethe izibophelelo ezenziwe ngezinto ezinamandla aphezulu njengentsimbi engagqwaliyo okanye intsimbi ye-alloy.

Iingxaki Zokuhambelana Nezinye Izinto

Kufuneka uqwalasele ukuhambelana xa usebenzisa izikrufu ze-galvanized kunye namandongomane nezinye izinto zokwakha. Ezinye iindibaniselwano zinokubangela ukugqwala okanye iikhemikhali eziya kwenza iprojekthi yakho ibe buthathaka.

Imithombo eliqela ezimeleyo ilumkisile ukuba umhlwa omhlophe nobomvu ukhawuleza uvele xa izibophelelo ze-hot dipped galvanized zivavanywa ngomthi onganyangekiyo. Ngokwengxelo ye-EPA, '[t]apha kubekho uvavanyo olukhawulezileyo oluqhutywe lishishini lezakhiwo olubonisa ukuba nezixhobo ezibhengeza ukuchasana okuphuculweyo nokugqwala ziqala ukubonisa iimpawu zokugqwala kwiiyure ezili-1000 zovavanyo olukhawulezileyo lobudala (olulingana neminyaka eli-16 yokuvezwa okufakiweyo) xa zisetyenziswa ngomthi onyangekisiweyo yi-ACQ.'

- Imithi elungisiweyo yokulondoloza isenokungahambelani nezikrufu ezifakwe i-zinc kunye ne-aluminium.

- Izikhonkwane zentsimbi engatyiwayo okanye izikhonkwane ze-hot dip galvanized ezenziwe nge-ASTM A153 Class D okanye ezinzima zisebenza kakuhle ngomthi ocociweyo.

- Xa uncamathisela iiphaneli zesinyithi kwimithi elungisiweyo, ungasebenzisa umqobo wokufuma phakathi kwemithi kunye nephaneli.

- Izinto zokubopha ezingahambelaniyo ziquka izikrufu ezifakwe i-zinc plated, izikrufu ezine-zinc-alloy headed, kunye nezikrufu ezingenasici.

Iimpendulo zeekhemikhali zinokwenzeka phakathi kweengubo ezigqunyiweyo kunye nekhonkrithi, ingakumbi ngexesha lokunyibilika. Le nkqubo ikhupha igesi ye-hydrogen kwaye yenza buthathaka unxibelelwano phakathi kwe-rebar egqunyiweyo kunye nekhonkrithi. Unyango lwe-chromate lunceda ekunciphiseni ezi ngxaki.

Isilumkiso:Soloko ujonga ukuba izibophelelo zakho ziyahambelana na nezinto ezikwiprojekthi yakho. Ukusebenzisa indibaniselwano engalunganga kunokubangela ukugqwala kwangethuba, amalungu abuthathaka, okanye nokonakala kwesakhiwo.

Ixesha lokusebenzisa izikrufu kunye neenati ezigayiweyo

Izicelo zeProjekthi ezilungileyo

Ufumana elona xabiso liphezuluizikrufu ze-galvanized kunye neenatikwiiprojekthi ezijongene nemozulu, ukufuma, okanye ukuvezwa ngaphandle. Iingcali zoshishino zicebisa ezi zibophelelo kwiindlela ezininzi ezibalulekileyo:

- Iiprojekthi Zangaphandle: Ungasebenzisa izikrufu ze-galvanized kwiingcingo, iidekhi, kunye nefenitshala yangaphandle. Ukumelana kwazo nokugqwala kugcina umsebenzi wakho uqinile nokuba lina okanye lilanga.

- Iiprojekthi zokwakha: Abakhi badla ngokukhetha izibophelelo ze-galvanized kwizakhelo zesakhiwo kunye nolwakhiwo ngokubanzi. Uzuza kukuqina kwazo kunye nexabiso eliphantsi.

- Umsebenzi wokhuni kunye neDecking: Izikrufu zegalvani zisebenza kakuhle ngamaplanga alungisiweyo. Zinceda ekuthinteleni amabala kunye nomonakalo womthi ngokuhamba kwexesha.

Ingcebiso:Imithetho yokwakha idla ngokufuna izibophelelo ze-galvanized ezifakwe kwi-hot-dipped, i-stainless steel, okanye i-silicon bronze kwiprojekthi ezinemithi egcinwe kakuhle. Xa uphahla, kufuneka usebenzise izibophelelo ze-galvanized ukuhlangabezana nemigangatho yokhuseleko.

| Uhlobo lwesicelo | Imfuneko yeFastener |

|---|---|

| Uphahla | Izibophelelo ze-galvanized zophahla lwentsimbi |

| Umthi ogcinwe ngendlela yokugcina izinto | Kufuneka intsimbi egqunywe nge-galvanized eshushu, intsimbi engatyiwayo, i-silicon bronze, okanye iziqhoboshi zobhedu. |

Ixesha Lokuqwalasela Ezinye Iindlela

Kuya kufuneka ujonge ezinye iintlobo zezincamathelisi ukuba iprojekthi yakho ijongene noxinzelelo olukhulu, iikhemikhali, okanye amanzi anetyuwa. Izincamathelisi zentsimbi engagqwaliyo zisebenza kakuhle kwiindawo zaselwandle, ekulungisweni kokutya, okanye kwiindawo zonyango. Zihlala ixesha elide kwaye ziyamelana nokugqwala ngcono kunentsimbi egalelwe ngesinyithi, ingakumbi kwiindawo ezinzima.

| Uhlobo lwe-Fastener | Eyona ilungileyo | Iingcali | Iingxaki |

|---|---|---|---|

| Yenziwe ngentsimbi eshayinayo | Ulwandle, ukutya, ezonyango, ngaphandle | Ihlala ixesha elide, ayimelani nokugqwala | Ixabiso eliphezulu |

| Isingxobo seZinc | Iindawo ezomileyo nezithambileyo | Ukhuseleko olusisiseko, olufikelelekayo nolulula | Ayifanelekanga kwiimeko ezinzima okanye ezimanzi |

| Ukwaleka kwePhosphate | Umkhosi, iimoto, imboni | Ukuthambisa kakuhle ngeoyile | Ukumelana nokugqwala okuphakathi |

Iingubo ze-galvanized zikhusela intsimbi emanzini olwandle, kodwa ityuwa kunye neekhemikhali zinokuzitshabalalisa ngokukhawuleza. Intsimbi engagqwaliyo inika ukusebenza okungcono kwexesha elide kwezi ndawo zinzima. Khetha isincamathelisi esifanelekileyo kwindawo yakho ukuze ugcine iprojekthi yakho ikhuselekile kwaye yomelele.

Ukukhetha iziQinisekiso zeGalvanized ezisemgangathweni

Ixesha leposi: Sep-24-2025