Ukugaya nge-galvanizing yindlela esetyenziswa kakhulu ekukhuseleni intsimbi kumhlwa. Ngokuyintloko,ibhafu yokugquma iglasiyiketile enkulu ye-zinc enyibilikisiweyo esetyenziselwa ukugquma iindawo zesinyithi. Xa intsimbi ecocekileyo ifakwa kule bath, i-zinc inamathela ngokukhawuleza kumphezulu, yenze isiphelo esomeleleyo nesimelana nokugqwala. I-Galvanizing ibikho kangangeminyaka engaphezu kwe-150, kodwa ihlala isebenza kakuhle kwaye inobuhlobo nokusingqongileyo. Enyanisweni, idla ngokukhankanywa njengenye yeenkqubo zokuthintela ukugqwala ezinobuhlobo nokusingqongileyo ezikhoyo. Isiphumo yintsimbi enokuphila amashumi eminyaka ngaphandle ngaphandle ngaphandle kokugcinwa okuncinci. Apha ngezantsi sichaza inyathelo ngenyathelo indlela inxalenye yentsimbi etshintsha ngayo ukusuka kwisinyithi esidala esinothuli ukuya kwi-zinc-armored, ngaphakathi kwebath ye-galvanizing.

Yintoni Ibhafu Evuselela I-Galvanizing?

Ibhafu yokugalela igesi yimbiza nje ye-zinc enyibilikisiweyo eshushu ukuya kuthi ga kwi-450°C (842°F). Iindawo zentsimbi zithotywa kule zinc ishushu, ebonakala ngathi yintsimbi elulwelo yesilivere. Ngexesha lokuntywiliselwa, i-zinc isabela kunye nentsimbi kwintsimbi, nto leyo eyenza unxibelelwano lwesinyithi phakathi kwe-zinc kunye nentsimbi. Enyanisweni, iinkampani zihlala zibiza oku ngokuthiukuntywila okushushuinkqubo – ukuntywilisela intsimbi ngokoqobo kwi-zinc “eshushu” (enyibilikisiweyo).

Le ndlela isebenza kakhulu. Ibhafu ye-zinc idla ngokugcinwa ngaphezulu kwe-98% ye-zinc ecocekileyo, kwaye iinkqubo zokuhambisa okanye ze-crane zigoba ngononophelo iziqwenga zentsimbi ukuze i-zinc ikwazi ukugubungela yonke ikona yenxalenye. Kwaneemilo ezingenanto okanye iityhubhu zizaliswe yi-zinc, ngoko ke ngaphakathi kugqunywe kunye nangaphandle. Njengoko esinye isikhokelo seshishini sisitsho, i-hot-dip galvanizing yinkqubo "yokuntywiliselwa ngokupheleleyo" - intsimbi intywiliselwa ngokupheleleyo kwaye i-zinc coatskonkeIntsimbi iphakanyiswa emva kwemizuzu embalwa inesikhumba esitsha sentsimbi esikhazimlayo kuyo.

Inkqubo Yokuntywilisela I-Hot-Dip (Qala Ude Ugqibe)

Inkqubo yokwenza i-galvanizing inezigaba ezibalulekileyo ezininzi. Nganye kufuneka yenziwe ngononophelo, kuba i-zinc iya kunamathela kuphela kumphezulu ococekileyo ngokugqibeleleyo. Ngokubanzi, la manyathelo ngala:

Ukucoca (Ukususa igrisi kunye nokuqhola):Okokuqala intsimbi icocwa kakuhle ukuze kususwe iioyile, igrisi, kunye nomhlwa okhululekileyo. Oku kudla ngokubandakanya isisombululo esishushu se-alkali (caustic) esisusa igrisi yentsimbi. Okulandelayo, intsimbi ifakwa kwi-asidi pickling bath (edla ngokunciphisa i-sulfuric okanye i-hydrochloric acid) ukuze idle i-mill scale kunye nomhlwa. Emva kokucoca, naluphi na uthuli oluqinileyo, ipeyinti okanye i-slag isuswa ngesandla okanye ngokuqhumisa. Ngamafutshane, zonke izinto ezingcolisayo kufuneka ziphele, kuba i-zinc ayizukunamathela kwintsimbi engcolileyo.

Ukufudumeza:Ngaphambi nje kokuba i-galvanize, intsimbi ecocekileyo ifakwa kwisisombululo se-flux, esidla ngokuba ngumxube we-zinc ammonium chloride. I-flux isusa amachaphaza okugqibela e-oxide kwaye ithintele i-oxidation entsha ngaphambi kokuba idibane. Kwezinye izityalo, "ingubo ye-flux" encinci idada phezu kwebhafu ye-zinc ukunceda ukunciphisa i-grisi yentsimbi njengoko ingena. Inyathelo lokujika libalulekile: liqinisekisa ukuba i-zinc enyibilikisiweyo ingenamanziintsimbi ngokulinganayo.

Ukuntywiliselwa kwiZinc Bath:Ngoku kuza intliziyo yenkqubo. Intsimbi elungisiweyo yehliswa kancinci (rhoqo nge-engile) kwi-kettle ye-zinc enyibilikisiweyo, edla ngokubanjelwa kwi-~450°C. Umfanekiso ongezantsi ubonisa imisebe yentsimbi ingena kwi-bath ye-zinc eshushu. Kwangoko nje intsimbi yakuthinta isinyithi esilulwelo, kuqalisa ukusabela. I-Zinc iqala ukuxubana nomphezulu wesinyithi, kwaye i-zinc elulwelo ijikeleza yonke indawo. Ngaphakathi kwi-bath, i-zinc kunye nesinyithi zenza iileya ezininzi ze-alloy nge-metallurgical reaction. Ngeli xesha (rhoqo imizuzu embalwa), uqweqwe luyakha ukuya kubukhulu balo obufanelekileyo. Umaleko weenyibilikisiweyoI-zinc inamathela kumphezulu wentsimbi ize iphole ukuze yenze ulusu lwangaphandle oluqinileyo.

Umfanekiso: Iindawo zentsimbi zifakwa kwibhafu yokuhlamba eshushu. I-zinc enyibilikisiweyo (isilivere elulwelo) ikhawuleza igqume intsimbi.

Abaqhubi bezityalo baqikelela ixesha lokuntywiliselwa ngononophelo. Kwiindawo ezininzi, ukuntywiliselwa imizuzu emi-4-5 kwanele. Iindawo ezinkulu okanye ezigqunyiweyo zinokuthatha ixesha elide ukuze zifikelele kubushushu obupheleleyo. Nje ukuba ifudunyezwe, inxalenye iphakanyiswa kancinci. Njengoko iphakama, nayiphi na i-zinc egqithisileyo iyaphuma - ngamanye amaxesha incediswa kukungcangcazela okanye ukujikelezisa isiqwenga. Iqokobhe elincinci le-zinc eliseleyo liya kuphola kwaye liqine, lihlala lithatha ukugqitywa okukhanyayo kwesilivere ngaphandle. Enyanisweni, intsimbi esandula ukugalelwa idla ngokukhazimla; "i-spangle" okanye ipateni efana nekhephu ye-zinc ekristaliweyo inokuvela kumphezulu njengoko iqina.

Ukupholisa (Ukudlulisa/Ukucima):Emva kokurhoxiswa, intsimbi egqunyiweyo iyapholiswa. Oku kungenziwa ngokupholisa umoya ngokulula okanye ngokucima intsimbi eshushu emanzini okanye ngokuhlamba ngekhemikhali. Akukho mfuneko yokulungisa okukhethekileyo - i-zinc/steel bond sele iqinile. Naluphi na umaleko obhityileyo wangaphandle we-zinc oxide (umhlwa omhlophe) onokuthi wenziwe uhlala ushiywe wodwa okanye uphathwe kancinci. Ngokungafaniyo neendawo ezipeyintiweyo, intsimbi egqunyiweyo idla ngokufunaakukho kugqitywa kwakhonaukuze ihlale ixesha elide.

Uhlolo:Inyathelo lokugqibela kukujonga okubonakalayo nobuchwepheshe ngokukhawuleza. Abahloli bajonga ukuba yonke indawo igqunyiwe kwaye balinganise ubukhulu. Ekubeni i-zinc ibopha kuphela kwisinyithi esicocekileyo, amabala amabi kulula ukuwabona (intsimbi engenanto ibonakala ikhanya). Iigeyiji ezisemgangathweni zilinganisa ubukhulu bengubo ukuqinisekisa ukuba iyahlangabezana neemfuno. Ngeli xesha intsimbi egqunyiweyo ilungele ukusetyenziswa, iqinisekisiwe ukuba iya kuxhathisa ukugqwala iminyaka emininzi.

Ngaphakathi eBhafini: Isinyithi kunye noKhuseleko

Okwenzekayo kwintsimbi engaphakathi kwe-zinc enyibilikisiweyo yikhemikhali eyinkimbinkimbi - kwaye yenye yamandla amangalisayo e-galvanizing. Njengoko intsimbi eshushu ihleli ebhafini, ii-athomu ze-zinc ziyasasazeka zibe yintsimbi ukuze zenze iikhompawundi ezininzi ze-intermetallic. I-American Galvanizers Association ibonisa oku ngecandelo elinqamlezileyo: kukho umaleko wangaphandle we-zinc ephantse yamsulwa (ebizwa ngokuba yi-eta layer) kwaye ngaphantsi kwayo kukho iileya ezintathu ze-alloy eqinileyo (ebizwa ngokuba yi-gamma, i-delta, i-zeta) kanye kwindawo yokujonga intsimbi. Okumangalisayo kukuba, ezi leya ze-zinc-iron alloy zikunzima kunentsimbi ethambileyoUmzekelo, imikrwelo emincinci ayingeni lula kule ngubo ineengqimba ezininzi. Enyanisweni, i-coating ene-galvanized iqinile kakhulu kwaye ayikhubeki.

Enye inzuzo ephambili kukukhusela i-cathodic (idini). I-Zinc isebenza kakhulu nge-electrochemical kunentsimbi. Ngamazwi alula, ukuba i-coating ikrwelwe kwintsimbi engenanto, i-zinc ejikelezileyo iya kuqala ikrwelwe, ikhusele intsimbi. Enyanisweni, i-hot-dip galvanizing idumile ngale nto: omnye umthombo uthi nokuba intsimbi engenanto (enkulu njenge-¼ intshi) ivezwe kwikrwelwe, "akukho mhlwa uya kuqala de yonke i-zinc ejikelezileyo itshiswe". Oku kuthetha ukuba ama-nick amancinci awadingi ukuphinda apendwe; i-zinc iyazincama ngokuhamba kwexesha.

Ukutyhubela iminyaka ukuchatshazelwa ngumoya nemvula kuguqula i-zinc ibe ziimveliso ezingezizo ezinobungozi (ii-oxide, ii-hydroxide, ii-carbonates) – i-patina engwevu onokuyibona kwisinyithi esidala esirhangqiweyo. i-zinc patina Kancinci kancinci yenza uqweqwe lwangaphandle olukhuselayo olucothisa ukugqwala ngakumbi. Enyanisweni, intsimbi egalelwe ngokupheleleyo idla ngokugqwala ngokuphindwe kangangama-30 kunentsimbi engenanto. Enyanisweni, oku kuthetha ukuba uqweqwe olugalelweyo luhlala iminyaka engama-50-60 nangaphezulu ngaphandle kokugcinwa, kuxhomekeke kwindawo engqongileyo.

Iingenelo ezimangalisayo zeUkugaya nge-galvanizing

I-Galvanizing inika izinto ezininzi "ezimangalisayo" onokuthi ungalindelanga kwi-metal coating elula:

1. Ugutyungelwe ngokupheleleyo:Ngenxa yokuba i-hot-dip galvanizing ifaka loo ndawo emanzini, igubungela nengaphakathi leendawo ezingenanto nangaphakathi kweetyhubhu. Imisonto kunye neekona ezifihliweyo zifumana i-zinc, ngokungafaniyo neepeyinti ezifakwe ibrashi. Oku kuntywiliselwa ngokupheleleyo kuthetha ukuba umhlwa awunakungena kwiindawo ezingalindelekanga.

2. Ukuqina okwakhelwe ngaphakathi:Iileya ze-zinc-iron ziqinile ngokwemvelo kwaye azinakuba nantlungu. Kwezinye iimvavanyo, uqweqwe lwentsimbi ye-galvanized lwaluphelileizihlandlo ezilishumiiyamelana nokugruzuka ngaphezu kwepeyinti eqhelekileyo. Umaleko we-zinc ococekileyo wangaphandle (eta) uthambile kwaye uthambile, unika ukumelana nokuchaphazeleka, ngelixa umaleko we-alloy wangaphakathi uqinile kunentsimbi. Olu qhagamshelo lwe-multilayer luthetha ukuba iindawo ezigqunyiweyo ziyasinda ekuphathweni nasekugugeni okurhabaxa.

3. Ukhuseleko Lokuziphilisa (lwamaKatolika):Njengoko kuphawuliwe, i-zinc "iya kuzincama" ukuze ikhusele intsimbi. Imikrwelo emincinci kwintsimbi egayiweyo ayiphumi mhlwa kuba i-zinc iyaqala ukubola (ekwabizwa ngokuba yi-cathodic protection). Kukho negama elithi, "sideways creep," malunga noko kwenzekayo kwintsimbi epeyintiweyo (umhlwa ohamba phantsi kwepeyinti) - kwaye i-galvanizing ngokuyintloko iyakuthintela.

4. Utshintsho olukhawulezileyo:Nangona izixhobo zinzima, inyathelo lokwenyani lokufaka i-galvanizing likhawuleza. Ukuxhoma isiqwenga uze usifake kwi-zinc kuthatha imizuzu embalwa kuphela. Ukulungiselela ikakhulu kukucocwa ngamakhemikhali, kwaye isityalo esisebenza kakuhle sinokusebenza i-odolo kwiintsuku ezimbalwa zizonke. Enyanisweni, iivenkile zanamhlanje zokufaka i-galvanizing zinenkonzo yeeyure ezingama-24 kwii-odolo ezincinci.

5. Ubomi beNkonzo ende:Ingubo egqunyiweyo ingakhusela intsimbi amashumi eminyaka ngaphandle kokupeyinta kwakhona. Kwiimeko eziqhelekileyo zangaphandle (kwimizi-mveliso okanye emaphandleni), kuqhelekile ukubona iminyaka engaphezu kwama-50 ngaphambi kokulungiswa kokuqala. Olu bude bexesha elide ludla ngokwenza ukuba ukupeyinta kube luncedo ngakumbi kunokupeyinta rhoqo ekuhambeni kwexesha.

6. Ubuhlobo kwiNdalo:Inkqubo yokwenza i-galvanizing icocekile. I-zinc esetyenzisiweyo iyaphinda isetyenziswe, kwaye akukho zinyibilikisi ze-organic eziguquguqukayo njengakwipeyinti. Intsimbi eyenziwe nge-galvanizing iphinda isetyenziswe ngokupheleleyo ekupheleni kobomi. Amaqela oshishino aqaphela ukuba i-galvanizing "mhlawumbi yeyona ndlela yokukhusela ukugqwala enobuhlobo nokusingqongileyo" ekhoyo.

7. Ukugqitywa okubonakalayo:Intsimbi egayiweyo idla ngokuba neempawu ezithilei-spangledokanye ipateni efana nekhephu kumphezulu wayo. Ezi kristale zesilivere ziinkozo ze-zinc eziqina, kwaye zinika ubuso obukhazimlisiweyo inkangeleko eyahlukileyo. Yindlela ebonakalayo yokuba kukho uqweqwe lokwenyani olushushu.

Izixhobo ezikumgangatho ophezulu: Isityalo sokugalela iipayipi sikaBonan Tech

Iivenkile ezinkulu zokufaka iigesi zisebenzisa oomatshini abasebenza nzima ukuqhuba ezi nkqubo ngokuqhubekayo. Umzekelo, iBonan Technology Co., Ltd., umenzi wezixhobo, igxininisa"Isityalo sokuGcina iiMpayipi esikumgangatho ophezulu"zakhiwe ngentsimbi ekumgangatho ophezulu kunye nezinto ezisetyenziswayo. Imigca yazo ezenzekelayo iphatha yonke into: iijigi zokuxhoma imibhobho, iitanki zokususa amafutha kwi-alkali, ii-asidi pickles, izitishi zokuhambisa amanzi, i-conveyor nge-zinc kettle, kunye neetanki zokucima. UBonan uqaphela ukuba izityalo zayo zokugaya iipayipi zenzelwe imveliso eqhubekayo kuzo zonke iidayamitha zepayipi.

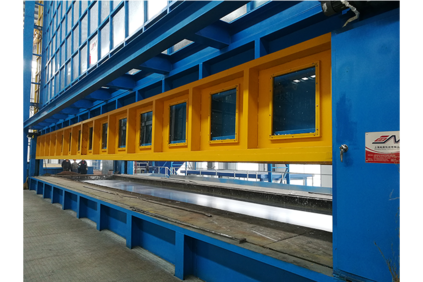

Umfanekiso: Umgca wokugaya umbhobho oqhubekayo osebenzayo. Ezi zityalo ezizenzekelayo zihambisa amacandelo ombhobho ngokucoca, ukufudumeza, kunye nokuhlamba i-zinc enyibilikisiweyo.

Kumgca weBonan Tech, inyathelo ngalinye lilawulwa ngononophelo. Enyanisweni, ukwenziwa kwe-galvanizing yepayipi kudla ngokulandela la manqanaba athile:

Ukucoca ngeCaustic:Imibhobho ingena kwibhafu eshushu yesodium-hydroxide ukuze isuse ioyile kunye nesikali sokugaya.

Ukuqhola i-asidi:Okulandelayo, badlula kwi-asidi bath (ngesiqhelo i-HCl okanye i-H₂SO₄) ukuze banyibilikise umhlwa kunye nee-oxides eziseleyo.

Ukuhlamba kunye nokuHlamba:Emva kokuhlamba, imibhobho ifakwa kwisisombululo se-zinc-ammonium chloride flux, ukuqinisekisa ukuba intsimbi ihlala ingena-oxide ngaphambi kokuba i-galvanize.

Ukomisa:Naluphi na umswakama okwintsimbi uyavuthuzwa okanye uphephuke ngumatshini wokomisa umoya.

Ukuntywiliselwa (Ibhafu yeZinc):Iipayipi zifakwa kwiketile ye-zinc enyibilikisiweyo. Idiphu eshushu izigquma kakuhle nge-zinc.

Ukucima:Ekugqibeleni, imibhobho eshushu egqunyiweyo ipholiswa ngokukhawuleza emanzini okanye kwibhafu yokucima ukuze ivale uphahla.

Yonke imibhobho ephumayo ngoku ine-zinc coating efanayo ukuthintela ukugqwala. Ngokwenkcazo kaBonan,"Umatshini Wokugalela Isinyithi Ozenzekelayo Weepayipi"iyakwazi ukuphatha "uluhlu lonke lweepayipi eziza kufakwa kwi-galvanized", iqinisekisa ukuba neepayipi ezinkulu kakhulu okanye ezincinci zifumana umaleko we-zinc ofanelekileyo.

Isiphelo

Ibhafu yokugquma i-galvanizing ayisiyo nje imbiza yesinyithi – liziko lenkqubo eqinisekisiweyo, eqhutywa yisayensi enika intsimbi ikhaka eliziphilisayo. Ukususela kumanqanaba okucoca ukuya ekuntywilisweni yi-zinc eshushu, inyathelo ngalinye lenziwa ngcono ukuvelisa uqweqwe oluqinileyo nolunamatheliswe ngesinyithi. Sibonile indlela intsimbi egqunyiweyo engamelani nje nokugqwala kodwa yenza kakuhle ngokumangalisayo – ngee-alloys ezininzi, ukuqina okukhulu, kunye neminyaka emininzi yobomi benkonzo.

Nokuba ungunjineli ochaza ibhulorho okanye umninimzi okhetha iintsika zocingo, ukuqonda inkqubo yokuhlamba nge-galvanizing kunceda ukuchaza isizathu sokuba intsimbi ye-galvanizing iphumelele kangaka. Ngamafutshane, ngaphakathi kwelo bhafu liphantsi le-zinc enyibilikisiweyo kukho inkqubo yokuzikhusela enamandla neyinkimbinkimbi ngokumangalisayo - eya kugcina izakhiwo zentsimbi zikhuselekile izizukulwana ngezizukulwana.

Ixesha leposi: Meyi-21-2025