I-Hot-DipUkugaya nge-galvanizing(HDG) inika ixabiso eliphezulu lexesha elide kwiiprojekthi zentsimbi. Ukubopha kwayo okungaqhelekanga kwesinyithi kunika ukuqina okungenakuthelekiswa nanto nxamnye nomonakalo. Inkqubo yokuntywiliselwa iqinisekisa ukugqunywa okupheleleyo, okufanayo okungenakuphindwa ziindlela zokutshiza. Olu khuselo luphindwe kabini lunciphisa kakhulu iindleko zokugcinwa kobomi.

Imakethi yehlabathi yokukhuthaza umbane kulindeleke ukuba ifikelele kwi-$68.89 yeebhiliyoni ngo-2025.umenzi wezixhobo zokugaya igesiyakha iphambiliimigca yokugaya i-galvanizingukuhlangabezana nale mfuno ikhulayo.

Izinto ezibalulekileyo ekufuneka ziqwalaselwe

- I-hot-dip galvanizingyenza intsimbi ibe namandla kakhulu. Idala iqhina elikhethekileyo elikhusela intsimbi ngcono kunepeyinti.

- Ukugaya ngentsimbi kuvala zonke iindawo zentsimbi. Oku kuthintela ukugqwala ukuba kuqale kwiindawo ezifihlakeleyo.

- Intsimbi egayiweyo iyonga imali ngokuhamba kwexesha. Ihlala ixesha elide kwaye ayifuni ukulungiswa kangako kunezinye iipeyinti.

Yintoni Eyenza I-Hot-Dip Galvanizing Ibe Lukhetho Oluphezulu?

I-Hot-Dip Galvanizing (HDG) yahlukile kwezinye iindlela zokukhusela ukugqwala. Ubuchule bayo buvela kumandla amathathu aphambili: i-fined metallurgical bond, i-complete immersion coverage, kunye nenkqubo yokukhusela esebenza kabini. Ezi mpawu zisebenza kunye ukubonelela ngentsebenzo engenakuthelekiswa nanto kunye nexabiso lexesha elide.

Ukuqina Okungenakuthelekiswa Nanto Nge-Metallurgical Bond

Ipeyinti nezinye izinto zokugquma zinamathela nje kumphezulu wentsimbi. I-hot-dip galvanizing yenza ukugqitywa okuya kuba yinxalenye yentsimbi ngokwayo. Inkqubo ibandakanya ukuntywiliselwa kwenxalenye yentsimbii-zinc enyibilikisiweyoishushu ukuya kuthi ga kwi-450°C (842°F). Olu bushushu buphezulu lubangela ukusasazwa kwe-diffusion reaction, idibanisa i-zinc kunye ne-iron kunye.

Le nkqubo yenza uthotho lweeleya ezahlukeneyo ze-zinc-iron alloy. Ezi leya zibotshelelwe ngesinyithi kwi-substrate yentsimbi.

- Umaleko weGamma: Eyona ikufutshane nentsimbi, ine-zinc emalunga ne-75%.

- Umaleko weDelta: Umaleko olandelayo uphuma, malunga ne-90% ye-zinc.

- Ileya yeZeta: Umaleko otyebileyo oqulethe malunga ne-94% ye-zinc.

- I-Eta Layer: Umaleko wangaphandle we-zinc ococekileyo onika i-coating isiphelo sayo sokuqala esikhanyayo.

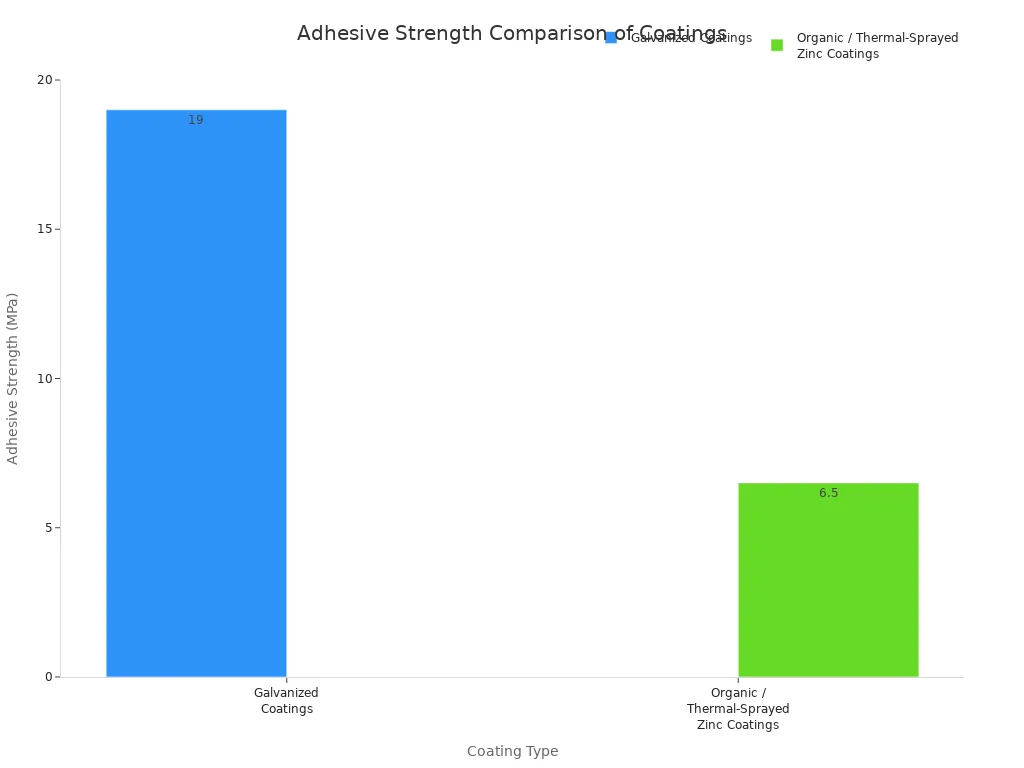

Ezi layer zidibeneyo zinzima kunentsimbi esisiseko, zibonelela ngokumelana okubalaseleyo nokukrweleka kunye nomonakalo. Layer zangaphakathi eziqinileyo ziyamelana nokukrweleka, ngelixa layer yangaphandle ye-zinc ecocekileyo inokufunxa iimpembelelo. Le bond yesinyithi inamandla kakhulu kuneebond zoomatshini zezinye iingubo.

| Uhlobo lokwaleka | Amandla eBond (psi) |

|---|---|

| I-Hot-Dip eyenziwe ngesinyithi | ~3,600 |

| Ezinye Iingubo | 300-600 |

Oku kuqina okukhulu kwebhondi kuthetha ukuba i-galvanized coating kunzima kakhulu ukuyixobula okanye ukuyiqhekeza. Iyakwazi ukumelana nobunzima bokuthuthwa, ukuphathwa kwayo, kunye nokwakhiwa kwayo kwindawo.

Ukhuseleko olupheleleyo loKhuseleko olupheleleyo

Ukugqwala kufumanisa indawo ebuthathaka. Iipeyinti ezitshizwayo, iprimer

s, kunye nezinye izinto zokugquma zisengozini yokusetyenziswa kweempazamo ezifana nokuvuza, ukubaleka, okanye iindawo ezilahlekileyo. Ezi mpazamo zincinci ziba ziindawo zokuqala umhlwa.

Ukuntywilisela i-galvanizing eshushu kususa le ngozi ngokuntywilisela ngokupheleleyo. Ukuntywilisela yonke into eyenziwe ngentsimbi kwi-zinc enyibilikisiweyo kuqinisekisa ukugqunywa ngokupheleleyo. I-zinc engamanzi ingena kuyo yonke indawo, ngaphezulu, nangaphaya kwayo.

Ikona nganye, umphetho, umthungo, kunye necandelo elingaphakathi elingenanto lifumana umaleko ofanayo wokhuseleko. Olu gquma "oluvela kumphetho ukuya kumphetho" luqinisekisa ukuba akukho ndawo zingakhuselekanga ezishiywe zichatshazelwe yindalo esingqongileyo.

Olu khuseleko lupheleleyo aluyondlela ilungileyo nje kuphela, kodwa yimfuneko. Imigangatho yehlabathi iyalela eli nqanaba lomgangatho ukuqinisekisa ukusebenza.

- I-ASTM A123ifuna ukuba ukugqitywa kwe-galvanized kuqhubeke, kube bushelelezi, kwaye kufane, kungabikho ndawo zingagqunywanga.

- I-ASTM A153imisela imithetho efanayo kwi-hardware, ifuna ukugqitywa okupheleleyo nokunamathelayo.

- I-ISO 1461ngumgangatho wamazwe ngamazwe oqinisekisa ukuba izinto ezenziwe ngentsimbi zifumana ukugqunywa okupheleleyo, okufanayo.

Le nkqubo iqinisekisa umqobo okhuselayo ohlala uhleli kulo lonke isakhiwo, into engenakukwazi ukuphinda yenziwe xa kutshizwa ngesandla okanye kusetyenziswa ibrashi.

Isenzo Esiphindwe Kabini: Umqobo kunye noKhuselo Lokuzincama

Ingubo egqunywe nge-galvanized ikhusela intsimbi ngeendlela ezimbini ezinamandla.

Okokuqala, isebenza njengeugqubuthelo lwesithintelo. Iileya ze-zinc zivala intsimbi ekudibaneni nokufuma kunye neoksijini. I-Zinc ngokwayo iyakwazi ukumelana kakhulu. Kwiindawo ezininzi zomoya, i-zinc idla ngokudla ngokuphindwe kalishumi ukuya kuma-30 kunentsimbi. Eli zinga lokudla ngokudla linika ikhaka elihlala ixesha elide.

Okwesibini, ibonelelaukhuseleko lokuzincama. I-Zinc isebenza kakhulu ngokwe-electrochemical kunentsimbi. Ukuba i-coating yonakaliswe ngumkrwelo onzulu okanye umngxuma wokubhoboza, i-zinc iya kuqala idle, "izinikele" ukuze ikhusele intsimbi eveziweyo. Olu khuselo lwe-cathodic luthintela umhlwa ekungeneni phantsi kwe-coating kwaye lunokukhusela amabala angenanto ukuya kuthi ga kwi-¼ intshi ububanzi. I-zinc ngokuyintloko isebenza njengomlindi wentsimbi, iqinisekisa ukuba nokuba umqobo uphulwe, isakhiwo sihlala sikhuselekile ekudleni. Le propati yokuziphilisa yinzuzo ekhethekileyo yeukugaya nge-galvanizing.

Inkqubo ye-HDG: Uphawu loMgangatho

Umgangatho ogqwesileyo wengubo egqunywe nge-hot-dip galvanized coating ayiyongozi. Ivela kwinkqubo echanekileyo, enamanqanaba amaninzi eqinisekisa ukugqitywa okuphezulu. Le nkqubo iqala kudala ngaphambi kokuba intsimbi ichukumise i-zinc enyibilikisiweyo.

Ukusuka ekuLungiselweni komphezulu ukuya kwiDiphu yeZinc enyibilikisiweyo

Ukulungiswa komphezulu ngendlela eyiyo yeyona nto ibalulekileyo ukuze kubekho upende ophumelelayo. Intsimbi kufuneka icoceke ngokugqibeleleyo ukuze kwenzeke ukusabela kwesinyithi. Le nkqubo ibandakanya amanyathelo amathathu abalulekileyo:

- Ukususa amafutha: Isisombululo esishushu se-alkali sisusa izinto ezingcolisayo eziphilayo ezifana nokungcola, amafutha, kunye neoyile kwintsimbi.

- Ukukha: Intsimbi ifakwa kwi-dilute acid bath ukuze kususwe isikali semill kunye nomhlwa.

- Ukufudumeza: Ukucwilisa kokugqibela kwisisombululo se-zinc ammonium chloride kususa naziphi na ii-oxides zokugqibela kwaye kufake umaleko okhuselayo ukuthintela ukuba umhlwa omtsha ungakheki ngaphambi kokuba ufakwe kwi-galvanizing.

Kuphela emva kokucoca okucokisekileyo apho intsimbi ifakwa khona kwibhafu ye-zinc enyibilikisiweyo, edla ngokufudunyezwa ukuya kuthi ga kwi-450°C (842°F).

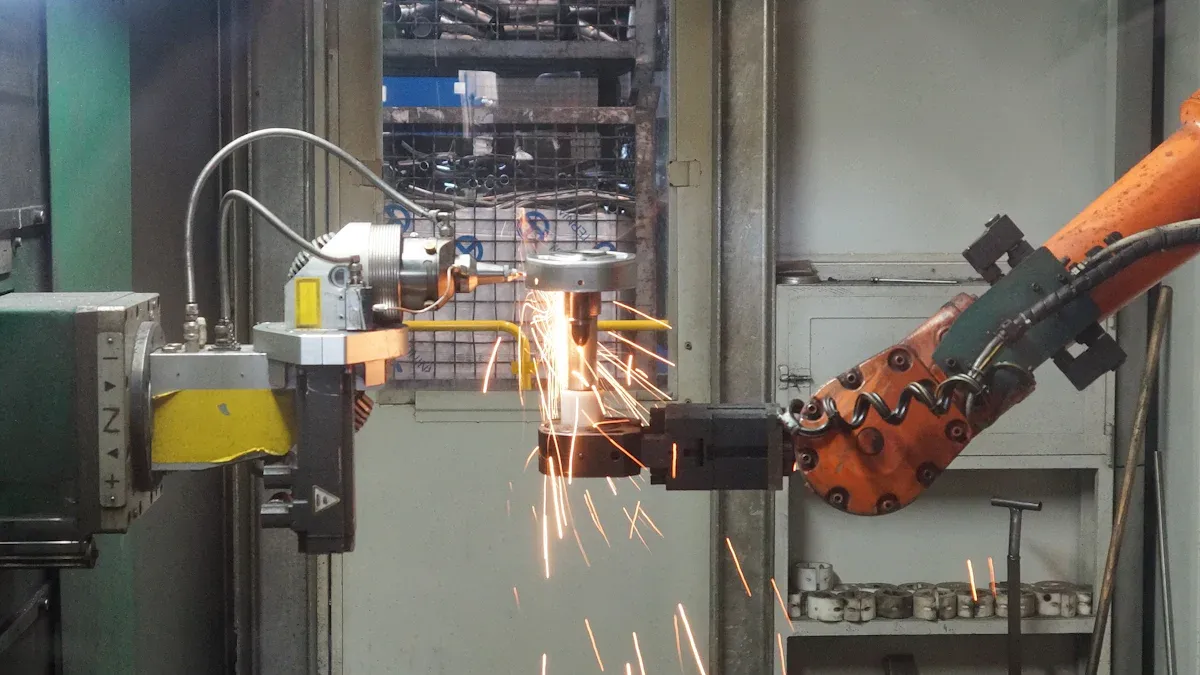

Indima yoMvelisi weZixhobo zokuGcina iGalvanizing

Umgangatho wenkqubo yonke uxhomekeke kumatshini. Umenzi wezixhobo ze-galvanizing onguchwephesha uyila kwaye wakhe imigca ephucukileyo eyenza i-HDG yanamhlanje ibe nokwenzeka. Namhlanje, umenzi wezixhobo ze-galvanizing ophambili ubandakanya i-automation kunye nee-real-time sensors zolawulo oluchanekileyo. Oku kuqinisekisa ukuba yonke inyathelo, ukusuka ekucoceni iikhemikhali ukuya kulawulo lobushushu, iyaphuculwa. Ngaphezu koko, iinkqubo zeenjineli zezixhobo ze-galvanizing ezinoxanduva ezihlangabezana nemigangatho engqongqo yokusingqongileyo kunye nokhuseleko, zihlala ziquka iinkqubo ezivaliweyo zokuphatha inkunkuma. Ubuchule bomenzi wezixhobo ze-galvanizing bubalulekile kwiziphumo ezihambelanayo nezisemgangathweni ophezulu.

Indlela Ubukhulu Bokugquma Okuqinisekisa Ngayo Ukuphila Ixesha Elide

Inkqubo elawulwayo, elawulwa ziinkqubo ezivela kumenzi wezixhobo ze-galvanizing eziphezulu, ichaphazela ngokuthe ngqo ubukhulu bokugqibela be-coating. Obu bukhulu buyindlela ephambili yokuqikelela ubomi benkonzo yentsimbi. I-zinc coating etyebileyo nefanayo inika ixesha elide lokukhusela kunye nokukhusela okuzincamayo. Imigangatho yeshishini ichaza ubukhulu be-coating obuncinci ngokusekelwe kuhlobo kunye nobukhulu bentsimbi, iqinisekisa ukuba inokumelana nendawo ekujoliswe kuyo amashumi eminyaka ngaphandle kokugcinwa kakhulu.

I-HDG vs. Ezinye iindlela: Uthelekiso lweNtsebenzo ka-2025

Ukukhetha inkqubo yokukhusela ukugqwala kufuna ukujonga ngononophelo ukusebenza, ukuqina, kunye neendleko zexesha elide. Nangona kukho ezinye iindlela,ukuntywila okushushuisoloko ibonakalisa ubungangamsha bayo xa ithelekiswa ngokuthe ngqo neepeyinti, ii-epoxies, kunye nee-primer.

Ukuchasana nePenti kunye neengubo ze-Epoxy

Iipeyinti kunye neengubo ze-epoxy ziifilimu eziphezulu. Zenza umaleko okhuselayo kodwa azidibani ngeekhemikhali nentsimbi. Lo mahluko uphambili ukhokelela kwizikhewu ezinkulu zokusebenza.

Iingubo ze-epoxy zinokwaphuka kakhulu. Zinokuqhekeka kwaye zixobuke, ziveze intsimbi engaphantsi. Nje ukuba umqobo uphukile, umhlwa ungasasazeka ngokukhawuleza. I-New York State Thruway Authority yafunda oku ngqo. Ekuqaleni basebenzise i-rebar ene-epoxy-coated ukulungisa iindlela, kodwa iingubo zaqhekeka ngokukhawuleza. Oku kwakhokelela ekuwohlokeni ngokukhawuleza kweendlela. Emva kokutshintshela kwi-rebar ene-galvanized ukulungisa ibhulorho, iziphumo zazimangalisa kangangokuba ngoku basebenzisa izinto ze-galvanized kwiiprojekthi zabo.

Imida yeengubo ze-epoxy iyacaca xa uzithelekisa ne-HDG.

| Uphawu | Iingubo ze-Epoxy | Ukuntywila okushushu |

|---|---|---|

| Ukubopha | Yenza ifilimu phezu komphezulu; akukho nxu lumano lweekhemikhali. | Yenza ikhonkco leekhemikhali kunye nentsimbi. |

| Indlela yokusilela | Ithanda ukuqhekeka nokuxobuka, nto leyo evumela ukuba umhlwa usasazeke. | Iimpawu zokuziphilisa zikhusela imikrwelo kwaye zithintele ukurhawuzelela komhlwa. |

| Ukuqina | Ingaqhekeka lula ngexesha lokuthuthwa nokufakwa. | Iileya ze-alloy ezihlala ixesha elide kakhulu ziyamelana nokukrala kunye nokuchaphazeleka. |

| Ukulungiswa | Akukho ndlela yokuzilungisa. Iindawo ezonakeleyo mazilungiswe ngesandla. | Ikhusela ngokuzenzekelayo iindawo ezincinci ezonakeleyo ngesenzo sokuzincama. |

Ukusetyenziswa kunye nokugcinwa kwazo kuzisa imingeni ebalulekileyo kwiingubo ze-epoxy.

- Umngcipheko Womonakalo: I-Epoxy iyaphuka. Ukukrweleka ngexesha lokuthuthwa okanye ukufakwa kunokubangela iindawo ezibuthathaka zokugqwala.

- Uvakalelo lwe-UVIntsimbi egqunywe nge-epoxy ifuna ii-tarps ezikhethekileyo zokugcina ngaphandle. Kufuneka ihlale igqunyiwe ukuthintela umonakalo ovela elangeni.

- Ukulahleka kokunamathela: Ukubopha kwentsimbi kwi-coating kubuthathaka ngokuhamba kwexesha, nokuba kugcinwe apho.

- Iindawo zaseLwandleKwiindawo ezikunxweme lolwandle, ii-epoxy coating zingenza kakubi kunentsimbi engenanto. Ityuwa kunye nokufuma kulula ukuzisebenzisa nasiphi na isiphene esincinci kwi-coating.

Kwiindawo ezikunxweme, i-HDG ibonisa ukuqina kwayo. Kwanakwiindawo ezinemimoya eneetyuwa ngqo, intsimbi eqinisiweyo inokuhlala iminyaka emi-5-7 ngaphambi kokuba ifune ukulungiswa kuqala. Iindawo ezikhuselekileyo kwisakhiwo esinye zinokuhlala zikhuselekile iminyaka eli-15-25 eyongezelelweyo.

Ngokuchasene neePrimers ezityebileyo zeZinc

Iiprimer ezityebileyo ze-zinc zihlala ziboniswa njengendlela yolwelo endaweni ye-galvanizing. Ezi primer ziqulathe ipesenti ephezulu yothuli lwe-zinc oluxutywe kwi-paint binder. Amasuntswana e-zinc abonelela ngokhuseleko olubi, kodwa inkqubo ixhomekeke kwi-mechanical bond, njengepeyinti eqhelekileyo.

I-hot-dip galvanizing, ngokuchaseneyo, idala iileya zayo zokukhusela ngokusebenzisa i-diffusion reaction kumaqondo obushushu aphezulu. Oku kwenza ii-alloys ze-zinc-iron zokwenyani ezidityaniswe nentsimbi. I-primer etyebileyo ye-zinc inamathela nje kumphezulu. Lo mahluko kwi-bonding ngundoqo ekusebenzeni okuphezulu kwe-HDG.

Uphawu Ukuntywila okushushu Iprimer etyebileyo yeZinc Indlela yokusebenza I-Metallurgical bond idala iileya ze-zinc-iron alloy ezihlala ixesha elide. Uthuli lwezinki kwi-binder lukhusela ngokuzincama. Ukunamathela Idityaniswe nentsimbi enamandla ebhondi angama-3,600 psi. Ukubopha koomatshini kuxhomekeke ekucocekeni komphezulu; buthathaka kakhulu. Ukuqina Iileya ze-alloy eziqinileyo kakhulu ziyamelana nokukrala kunye nempembelelo. Ukwaleka okuthambileyo okufana nepeyinti kunokukrwelwa okanye kuqhekezwe lula. Ukufaneleka Ilungele ukusetyenziswa kwentsimbi yesakhiwo xa isetyenziswa nzima kwaye ihlala ixesha elide. Eyona ilungileyo xa kusenziwa i-touch-ups okanye xa i-HDG ingenakwenzeka. Nangona iiprimer ezityebileyo kwi-zinc zikhusela kakuhle, azinakulingana nokuqina kunye nobude bengubo yokwenyani egqunywe nge-galvanized. Ukusebenza kakuhle kweprimer kuxhomekeke ngokupheleleyo ekulungisweni nasekusetyenzisweni komphezulu ngokugqibeleleyo, kwaye ihlala isengozini yokukrweleka kunye nokonakala komzimba.

Ukujongana nokugxekwa okuqhelekileyo kwe-HDG

Ingcamango ephosakeleyo eqhelekileyo malunga ne-hot-dip galvanizing yindleko yayo yokuqala. Ngaphambili, i-HDG ngamanye amaxesha yayibonwa njengokhetho olubiza kakhulu kwangaphambili. Nangona kunjalo, oko akusekho ngo-2025.

Ngenxa yamaxabiso e-zinc azinzileyo kunye neenkqubo ezisebenzayo ngakumbi, i-HDG ngoku inokhuphiswano olukhulu kwixabiso lokuqala. Xa kujongwa iindleko zomjikelo wobomi, i-HDG phantse isoloko iyeyona ndlela ingabizi kakhulu. Ezinye iinkqubo zifuna ukulungiswa rhoqo kunye nokuphinda zisetyenziswe, nto leyo eyongeza iindleko ezinkulu kubomi beprojekthi.

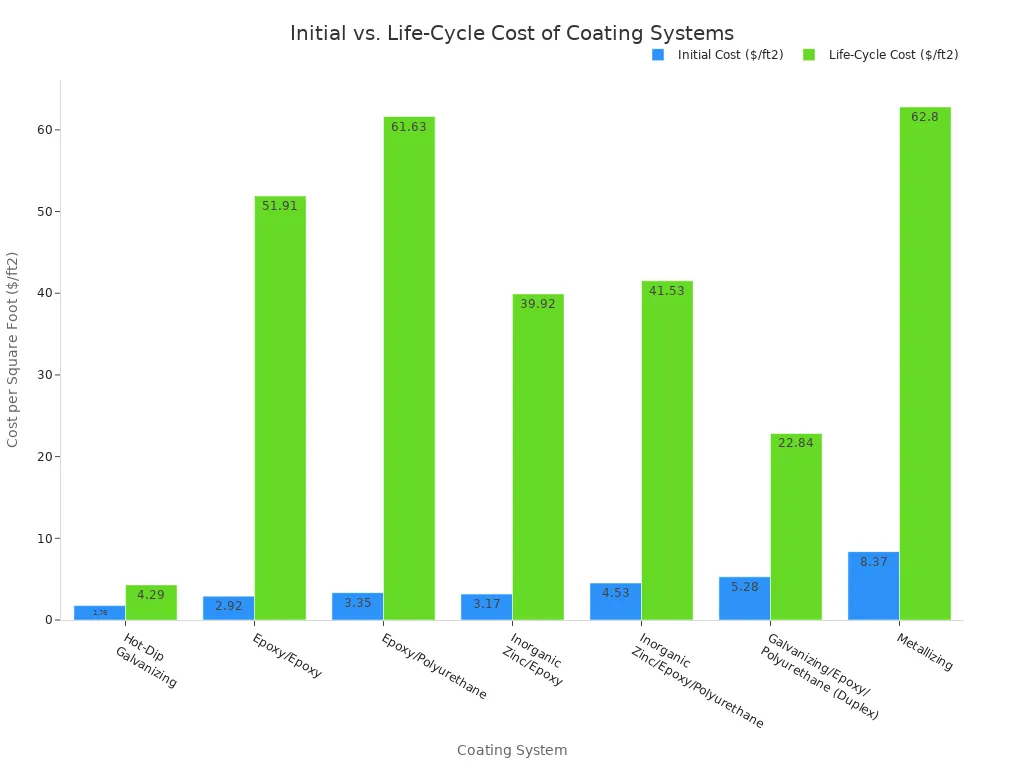

Umthombo womfanekiso:statics.mylandingpages.co I-American Galvanizers Association ibonelela nge-Life-Cycle Cost Calculator (LCCC) ethelekisa i-HDG nezinye iinkqubo ezingaphezu kwama-30. Idatha ibonisa rhoqo ukuba i-HDG igcina imali. Umzekelo, kolunye uphando lwebhulorho enobomi boyilo lweminyaka engama-75:

- Ukuntywila okushushuyayinexabiso lobomi$4.29 ngenyawo yesikwere.

- I-AnI-Epoxy/iPolyurethaneinkqubo yayinexabiso lobomi$61.63 ngenyawo yesikwere.

Lo mahluko mkhulu uvela ekusebenzeni kwe-HDG ngaphandle kokugcinwa. Isakhiwo esenziwe nge-galvanized sinokuhlala iminyaka engama-75 nangaphezulu ngaphandle kokufuna umsebenzi omkhulu. Oku kwenza ukuba sibe lolona tyalo-mali lukrelekrele kakhulu kwiiprojekthi zexesha elide.

Ixesha leposi: Okthobha-28-2025