Ukulibaziseka okuqhubekekayo kudla ngokuba yingxaki kwimisebenzi yokugaya i-galvanizing. Amaxesha okulinda ii-crane, ukucocwa okungaguqukiyo kwe-iibhafu zokufaka i-galvanizing, kwaye iingxaki zenkqubo ziingxaki eziqhelekileyo. Ukuziqhelanisa okujoliswe kuko kusombulula ngokuthe ngqo ezi ngxaki. Ukusebenzisa izisombululo ezithile ezifana ne-advancedIzixhobo Zokuphatha Izintoinyusa imveliso, inciphisa iindleko zokusebenza, kwaye iphucula kakhulu ukhuseleko lwabasebenzi abajikeleze umzi-mveliso.

Izinto ezibalulekileyo ekufuneka ziqwalaselwe

- Ukwenziwa kwezinto ngokuzenzekelayo kulungisa ukulibaziseka okuqhelekileyo kwiizityalo zokugaya igesiYenza imisebenzi yekreyini ikhawuleze kwaye ichaneke ngakumbi.

- Izixhobo ezizenzekelayo zigcina i-zinc bath icocekile. Oku kuphucula umgangatho wemveliso kwaye kwenza inkqubo ikhuseleke ngakumbi kubasebenzi.

- Iinkqubo ezizenzekelayo zihambisa izinto kakuhle phakathi kwamanyathelo. Oku kuyayekisa imiqobo kwaye kwenza wonke umgca wemveliso usebenze ngcono.

Ukusebenza kweCrane okungasebenzi kakuhle kunye nokuphathwa ngesandla

Ingxaki: Ukulibaziseka kweKreyini yesandla kunye neengozi zokhuseleko

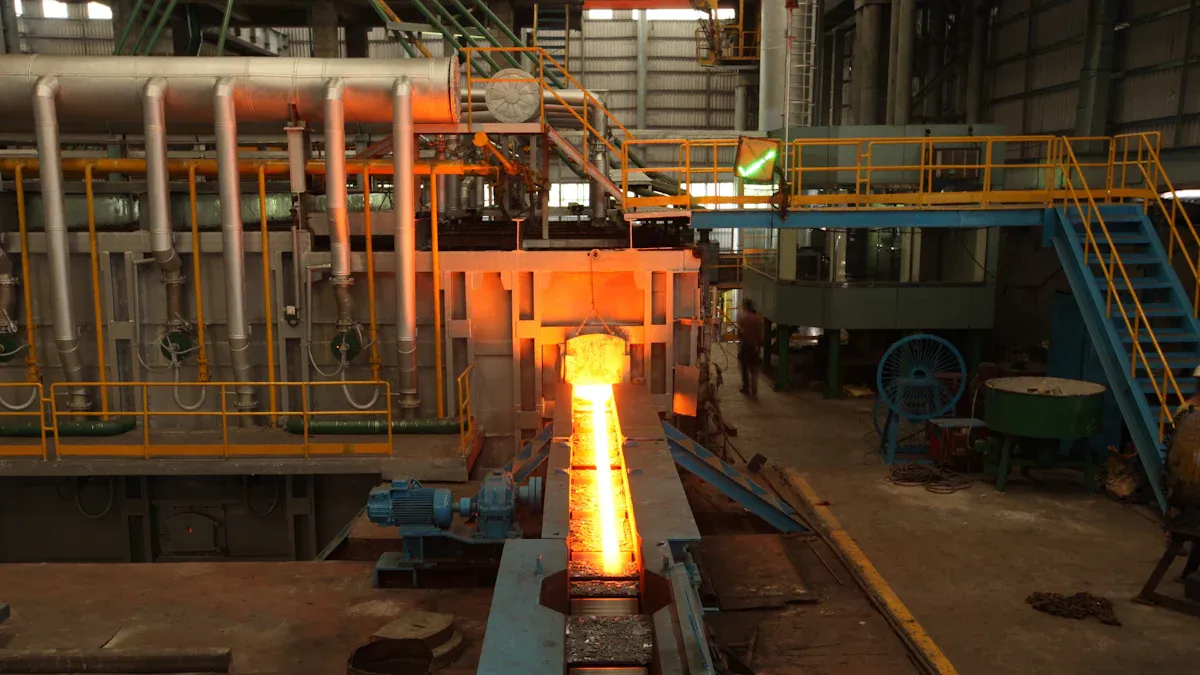

Iikhreyini ezenziwe ngesandla zihlala zibangela ukulibaziseka kwemveliso kwizityalo ezisebenzisa i-galvanizing. Ukusebenza kuxhomekeke ngokupheleleyo kubukho kunye nesakhono somntu osebenza. Oku kuxhomekeka kwazisa ukuguquguquka kunye namaxesha okulinda, njengoko ii-jigs kunye nezixhobo zilandelana ukuze ziphakanyiswe kwaye zihanjiswe. Iinkqubo ezenziwe ngesandla zinemida esisiseko kwisantya kunye nokuchaneka, okudla ngokubangela imiqobo ebalulekileyo yemveliso.

Ubusazi?Umzuzu ngamnye umgca wemveliso olinda ikreyini ngumzuzu wokulahleka kwemveliso, nto leyo echaphazela ngokuthe ngqo inzuzo kunye neeshedyuli zokuhanjiswa.

Olu libaziseko aluyongxaki yokusebenza kakuhle nje kuphela; lukwabeka nemingcipheko yokhuseleko. Ukuphathwa ngesandla kwezinto ezinzima, ezishushu, okanye eziphathwe ngamachiza kwandisa amathuba eengozi kunye neempazamo zomsebenzisi. Ukuphucula eli nqanaba kubalulekile ekudaleni indlela yokusebenza ekhuselekileyo nenemveliso ngakumbi, eqala ngcono.Izixhobo Zokuphatha Izinto.

Isisombululo: Iinkqubo zeCrane ezizenzekelayo kunye neeHoist

Iikhreyini ezizenzekelayo kunye neenkqubo zokuphakamisa zibonelela ngesisombululo esithe ngqo nesisebenzayo. Ezi nkqubo zenza imisebenzi yokuphakamisa ephindaphindwayo ngokuzenzekelayo, zikhawulezisa amaxesha okujikeleza kwaye zinciphise ixesha lokungasebenzi elinxulunyaniswa nemisebenzi yezandla. Iikhreyini zombane ezidityaniswe neekhreyini eziphezulu zakha isiseko somgca wemveliso wanamhlanje, izinto ezihambayo ezinesantya kunye nokunyamezela okungenakulinganiswa neenkqubo zezandla. Olu zenzekelayo lubalulekile ekuphakamiseni okuphezulu, okuphindaphindwayo apho ukuhambelana kubalulekile.

Iikhreyini zanamhlanje ezizenzekelayo zenzelwe imeko-bume edinga umbane. Zibonelela ngolawulo oluchanekileyo nolucwangcisiweyo kuyo yonke intshukumo.

| Ipharamitha | Ixabiso eliqhelekileyo |

|---|---|

| Umthamo woMthwalo | Iitoni ezi-5 ukuya kwezili-16 (zingenziwa ngokwezifiso) |

| Isantya sokuphakamisa i-Hoist | Ukuya kuthi ga kwi-6 m/min (iguquguqukayo) |

| Isantya sokuHamba ngeCrane | Ukuya kuthi ga kwi-40 m/min (iguquguqukayo) |

| Inkqubo yoLawulo | I-PLC isebenza kude |

| Iimpawu zoKhuseleko | Ukuphepha ukungqubana, ukujonga umthwalo |

Ngokudibanisa obu buchwepheshe, izityalo zinokwenza ngcono yonke indlela ezisebenza ngayo. Iikhreyini ezizenzekelayo zisebenza kakuhle nezinyeIzixhobo Zokuphatha Izintoukuqinisekisa utshintsho oluhamba kakuhle phakathi kweenkqubo. Olu phuculo luphucula imveliso, luphucula ukhuseleko ngokususa abasebenzi kwiindawo ezinobungozi, kwaye lwenza lonke uluhlu lweZixhobo zoLawulo lweZixhobo lusebenze ngcono.

Ukucocwa kweKettle okungahambelaniyo kunye neNkunkuma yeZinc

Ingxaki: Ukungasebenzi kakuhle kokulahlwa kwenkunkuma ngesandla kunye nokunciphisa ubushushu

Ukugcinwa kwekettle ngesandla ngumthombo omkhulu wokuguquguquka kwenkqubo kunye nenkunkuma. Ukugxojwa okungasebenzi kakuhle kuvumela iikhompawundi ze-zinc-iron ukuba zingcolise imveliso yokugqibela, zenzakalise ukugqitywa kwayo. Ngokufanayo, ukuba abasebenzi abazisusi ngokufanelekileyo ii-zinc skimmings (i-oxidized zinc) kumphezulu webhafu, ezi ntsalela zinokuhlala kwintsimbi ngexesha lokurhoxiswa. Oku kugxojwa okungasebenzi kakuhle kuvumela ii-oxides ukuba zivaleleke ngaphakathi kwengubo ye-galvanized, nto leyo edala ukungalungelelani okuchaphazela kakubi umgangatho wokubonakala kwemveliso.

Ngaphandle komgangatho wemveliso, ukulahlwa kwenkunkuma ngesandla kunegalelo elikhulu emzimbeni kubasebenzi. Le nkqubo ibabeka esichengeni kwiingozi ezininzi zokhuseleko.

Iingozi eziqhelekileyo zokulahlwa ngesandla

- Uxinzelelo lwemisipha emqolo ongezantsi nasezingalweni ngenxa yokuphakamisa izixhobo ezinzima.

- Amatyala aqinisekisiweyo e-carpal tunnel syndrome kunye nokwenzakala esihlahleni.

- Ukuvezwa rhoqo kubushushu obugqithisileyo obuvela kwi-zinc enyibilikisiweyo.

- Ukuma okungacacanga kwamagxa kunye nomzimba okwandisa umthwalo womzimba.

Olu ngxubakaxaka lweziphumo ezingahambelaniyo kunye neengozi zokhuseleko kwenza ukucocwa kweketile ngesandla kube yeyona nto iphambili ekusetyenzisweni ngokuzenzekelayo.

Isisombululo: Izixhobo zokuGxotha iiRobotic kunye neZixhobo zokuSkimming

Izixhobo zokulahla inkunkuma kunye nezixhobo zokuskena nge-robotic zibonelela ngenye indlela echanekileyo nethembekileyo. Ezi nkqubo ngokuzenzekelayo zisebenza ngokungaguquguqukiyo, ziphucula ngokuthe ngqoinkqubo yokwenza i-galvanizing. Iintshukumo zabo ezilawulwayo zisusa inkunkuma kwaye zisuse umphezulu wokuhlamba ngaphandle kokudala ukuxinana okungafunekiyo kwi-zinc enyibilikisiweyo. Oku kukhokelela kwindawo yeketile ecocekileyo nezinzileyo.

Iinkqubo ezizenzekelayo zisebenzisa ubuchwepheshe obuphambili njengombono womatshini ukuchonga nokususa inkunkuma ngokufanelekileyo. Olu phuculo lunciphisa ukusetyenziswa kwe-zinc kunye namandla ngokuphelisa imijikelo yokucoca engeyomfuneko. Iingenelo zicacile:

- Ziqinisekisa ukuhlamba okucocekileyo, zithintela "iindawo ezishushu" ezikufutshane ukuze zintywiliselwe ngokulinganayo.

- Basusa ubumdaka ngentshukumo ezilawulwayo nezithambileyo.

- Zisebenza ngokweshedyuli ehambelanayo, zigcina ubunyulu obufanelekileyo be-zinc.

Ngokuzenzekela lo msebenzi ubalulekileyo,izityalo zokugaya igesiukunciphisa inkunkuma ye-zinc, ukuphucula umgangatho wokugquma, kunye nokususa abasebenzi kwimisebenzi enobungozi.

Ukuphucula ukuhamba komsebenzi ngezixhobo zokuphatha izixhobo ezenzekelayo

Ingxaki: Iingxaki Zangaphambi Konyango Nasemva Konyango

Ukusebenza kakuhle komgca we-galvanizing kudla ngokonakala ngexesha lotshintsho. Ukunyakaza ngesandla kwezinto phakathi kweetanki zangaphambi konyango, iketile ye-galvanizing, kunye neendawo zokupholisa emva konyango kudala iingxaki ezinkulu. Iijigi ezifakwe intsimbi kufuneka zilinde i-crane kunye nomsebenzisi okhoyo, nto leyo ebangela ukuba kubekho imigca kunye nezixhobo zokungaqhubi kakuhle. Le nkqubo yokuma nokuhamba iphazamisa isigqi semveliso, inciphisa ukudlula, kwaye yenza kube nzima ukugcina ixesha lokucubungula elihambelanayo kumthwalo ngamnye. Ukulibaziseka ngakunye kwezi ndawo zokudlulisa kuchaphazela umgca wonke, kunciphisa amandla esityalo kunye nokusebenza kakuhle.

Isisombululo: Iinkqubo zokuDlulisa eziZenzekelayo ngokupheleleyo

Iinkqubo zokudlulisa izinto ngokuzenzekelayo ngokupheleleyo zibonelela ngesisombululo esithe ngqo kwezi ngxaki zomsebenzi. Esi sixhobo sokuphatha izinto esisemgangathweni sisebenzisa indibaniselwano yeebhanti zokuhambisa, iirola, kunye nolawulo olukrelekrele ukuze zenzele kwaye zilungelelanise ukuhamba kwezinto ngokuzenzekelayo. Ezi nkqubo zenzelwe ukuhlanganiswa okungenamthungo neziseko zezityalo ezikhoyo, amanqanaba okudibanisa afana nezitofu zokufudumeza, iibhafu zokufaka i-galvanizing, kunye nezixhobo zokupholisa. Ukuseta okuqhelekileyo kubandakanya ibhanti yokuhambisa eneentonga zokubeka izinto ukuze zikhusele izinto kunye nebhokisi yokupholisa ukuze kuphole kakuhle umoya namanzi kwiindawo zentsimbi.

Ngokuzenzekela yonke inkqubo yokudlulisa, ezi nkqubo zisusa ukungenelela ngesandla kunye nokulibaziseka okunxulumene noko. Iisensa ezikrelekrele kunye neenkqubo zolawulo ziqinisekisa ukuqala, ukuma, kunye nokubeka ngokuchanekileyo ngokuzenzekelayo ukuze umsebenzi uhambe kakuhle kwaye uqhubeke. Eli nqanaba lolawulo liphucula ukuhambelana kunye nokuzinza kwenkqubo yonke.

Ulawulo lweNkqubo oluPhuculweyoIinkqubo zolawulo eziphambili ezifana neProgrammable Logic Controllers (PLCs) kunye neenkqubo zokwenziwa kwemveliso (MES) zibonelela ngolawulo olupheleleyo lomgca. Zilawula iindlela zokupheka ezisebenzayo kwaye zibonelela ngokulandeleka ngokupheleleyo ukusuka kwizinto eziluhlaza ukuya kwimveliso egqityiweyo.

Olu qhagamshelo lolawulo olukrelekrele kunye neZixhobo zoLawulo lweZinto eziqinileyo luphucula ukusebenza kwenkqubo, luphucula ukusebenza kakuhle kwemveliso, kwaye ludala imeko yokusebenza ekhuselekileyo neqikelelekayo.

Ukwenziwa kwezinto ngokuzenzekelayo kuphelisa ngokufanelekileyo ukulibaziseka okuphindaphindiweyo ekuphathweni ngesandla nasekutshintsheni kwenkqubo. Iikhreyini ezizenzekelayo kunye nezixhobo zerobhothi zizisombululo eziqinisekisiweyo eziphucula ukhuseleko. Zikwanyusa imveliso, idatha ebonisa ukuba ukwenziwa kwezinto ngokuzenzekelayo kuphucula ukusebenza nge-10% kwiindawo ezininzi. Ukuvavanya iingxaki ezithile zomgca othile kuchonga apho icebo elijoliswe kulo lizisa khona imbuyekezo ephezulu.

Ixesha leposi: Disemba-15-2025