Abaphathi bachonga izikhewu ezibalulekileyo zokusebenza, ukusuka ekungasebenzi kakuhle kwesithando ukuya kwiinkqubo zolawulo ezindala.Umzi-mveliso woMgca weMveliso yeGalvanizingibeka phambili uphuculo olunembuyekezo ephezulu, kuqukaIinxalenye ezincinci zeGalvanizing imigca (Robort)Basebenzisa uhlaziyo kwizigaba ezicwangcisiweyo ukunciphisa ixesha lokungasebenzi kwemisebenzi.

Into ebalulekileyo ekufuneka uyithathe:Le ndlela inobuchule inika iingenelo ezibonakalayo. Ezi ziquka umgangatho wemveliso ophucukileyo, iindleko zokusebenza eziphantsi, kunye nokwanda kwenzuzo iyonke.

Izinto ezibalulekileyo ekufuneka ziqwalaselwe

- Qala ngokuhlola ngokupheleleyo i-filler yakho ukuze ufumane iingxaki uze uthathe isigqibo sokuba uza kulungisa ntoni kuqala.

- Phucula iinkqubo ezindala ngetekhnoloji entsha ukuze i-mill yakho isebenze ngcono kwaye wonge imali.

- Qeqesha iqela lakho kwizixhobo ezintsha kwaye uqhubeke uphucula ukuqinisekisa ukuba imboni yakho isebenza kakuhle.

Inyathelo 1: Yenza uhlolo olupheleleyo lomgca

Uphuculo oluphumelelayo luqala ngophicotho olucokisekileyo. Eli nyathelo lokuqala libonelela ngesicwangciso esicacileyo sokuphucula. Lichonga ubuthathaka obuthile ngaphambi kokuba kubekho naluphi na utyalo-mali. Uphicotho oluneenkcukacha lunceda abaphathi baqonde imeko yokwenyani yemisebenzi yabo.

Iingxaki zeNkqubo yokuNgqinisisa

Abaphathi baqala ngokuchonga iindawo ezicothisa imveliso okanye eziwohloza umgangatho. Ezi ngxaki zihlala zizibonakalisa njengeziphene eziphindaphindayo kwimveliso. Ukuhlolwa ngononophelo kunokufumanisa imiba emininzi eqhelekileyo. Ezi ngxaki zichaphazela ngokuthe ngqo inzuzo kunye nolwaneliseko lwabathengi.

- Izinto ezingafunekiyo: Amasuntswana amancinci e-zinc-iron alloy anokonakalisa ukumelana nokugqwala kwengubo.

- Amabala AngenantoEzi ndawo zingagqunywanga zidla ngokubangelwa kukungalungiselelwa kakuhle komphezulu okanye i-aluminium egqithisileyo eketileni.

- Ukuqhekeka: Iingubo ezinzima zinokubangela uxinzelelo oluphezulu, nto leyo ebangela ukuba umaleko we-zinc uphume kwintsimbi.

- Amaqhuma kunye nokubaleka: Oku kwenzeka ngenxa yesantya sokurhoxa esingachanekanga okanye amaqondo obushushu angafanelekanga okuhlamba.

- Ukugquma: Amabala angwevu amdaka anokwakheka ngenxa yobuninzi be-silicon okanye i-phosphorus kwintsimbi.

Vavanya iMpilo yeNkqubo

Okulandelayo, amaqela kufuneka ahlole imeko yezixhobo eziphambili. Oku kuqukaisithando somlilo, iidrive, kunye neenkqubo zolawulo. Inkqubo yokuguga inokuba nzima ukugcina isantya kunye nobushushu obuhambelanayo. Oku kuchaphazela ngokuthe ngqo ukwenziwa kunye nokusetyenziswa kwamandla. I-Galvanizing Production Line Factory yanamhlanje kufuneka ilungelelanise amandla ayo kunye nesantya sayo sokusebenza.

Isantya somgca we-galvanizing sidla ngokuba phakathi kwe-3-30 m/min. Umthamo wombane ohambayo yeyona nto ibalulekileyo ekufuneka iqwalaselwe ukuze kuhambelane isantya somgca kunye nobungakanani bemveliso.

Hlalutya idatha yokusebenza

Idatha inika ulwazi oluchanekileyo malunga nokusebenza kakuhle kwemigca. Abaphathi kufuneka baqokelele kwaye bahlalutye izalathisi zokusebenza eziphambili (ii-KPI). Olu lwazi lugxininisa iindlela ezisetyenziswayo kwaye luqinisekisa impembelelo yeengxaki. Ukulandelela ezi milinganiselo kubalulekile ekulinganiseni impumelelo yophuculo lwexesha elizayo. Amanqaku edatha aphambili aquka:

- Imveliso yemveliso

- Ukusetyenziswa kwezixhobo

- Iindleko zolondolozo

Inyathelo lesi-2: Beka phambili uPhuculo oluPhambili loBugcisa

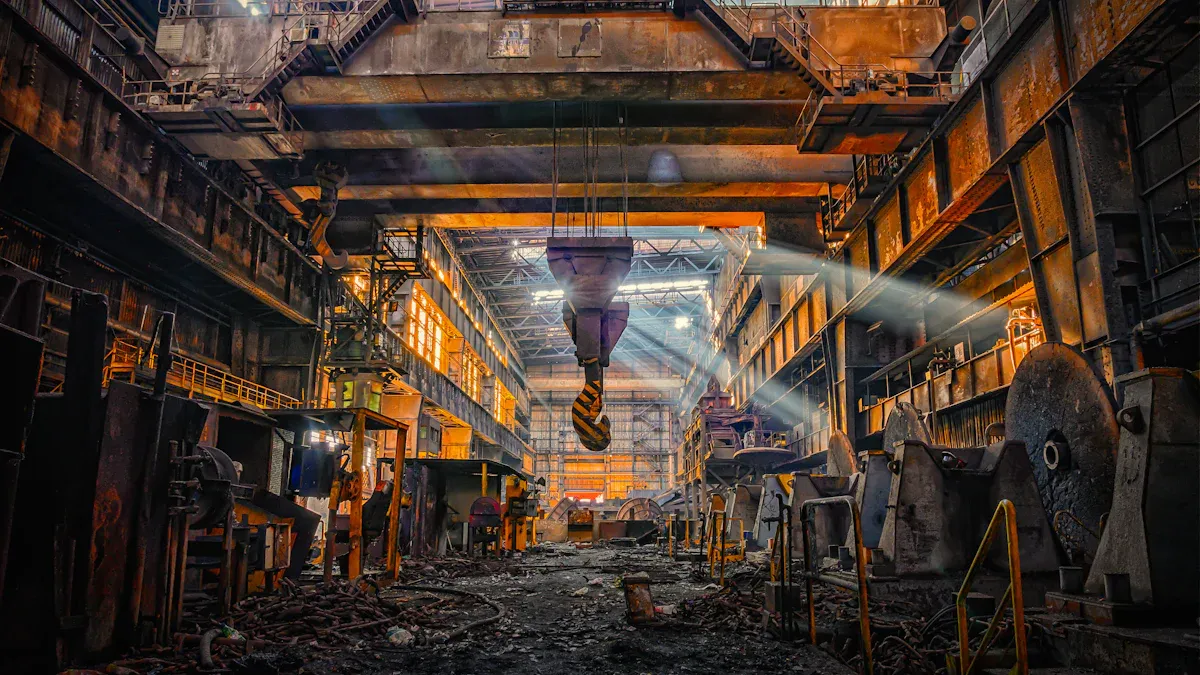

Umthombo womfanekiso:susa iplastikhi

Emva kophicotho olucokisekileyo, abaphathi banokuchonga ukuba zeziphi iinguqu zobugcisa eziya kuzisa imbuyekezo ephezulu kutyalo-mali. Ukugxila kulawulo lwenkqubo, iinkqubo zoomatshini, kunye nolawulo lomgangatho kudala isiseko esinamandla sokusebenza kwanamhlanje, okusebenzayo, kunye nenzuzo.

Yenza uLawulo lweNkqubo kunye nokuZenzekela kube yimihla ngemihla

Iinkqubo zolawulo eziphelelwe lixesha zingumthombo ophambili wokungasebenzi kakuhle.Ukuzenzekela kwanamhlanjeyenza kube lula ukuvelisa, inciphise ixesha lokungasebenzi, kwaye ivumela utshintsho olukhawulezileyo phakathi kwamanqanaba entsimbi ahlukeneyo. Ukuphucula ukuya kwinkqubo ye-automation yeNqanaba lesi-2 kubonelela ngengqondo ephakathi kulo lonke umgca. Iimpawu eziphambili ziquka:

- Inkqubo yeKhompyutha yoLawulo lweNkqubo ngexesha langempela.

- Ukufuduselwa kwekhowudi endala (njenge-FORTRAN) kwiilwimi zanamhlanje ezifana ne-C#.

- Uphuhliso lwe-interfaces zomsebenzisi ezisebenziseka lula (ii-UI).

- Utshintsho ukusuka kwindawo yokugcina idatha esekwe kwifayile ukuya kwiindawo zokugcina idatha ze-Oracle eziqinileyo.

IiModern Programmable Logic Controllers (PLCs) kunye neeHuman-Machine Interfaces (HMIs) zinika amandla abaqhubi ukuba benze izigqibo ezikrelekrele nezikhawulezayo. Ezi nkqubo zibonelela ngokusebenza okubonakalayo ngokupheleleyo ngeedeshibhodi zexesha langempela. Abaqhubi banokujonga izalathisi zokusebenza eziphambili (ii-KPI) ezifana ne-Overall Equipment Effectiveness (OEE) kunye ne-throughput ukuchonga iindlela kunye nokuphucula ukusebenza kakuhle.

I-HMI eqondakalayo isebenza njengebhulorho phakathi komqhubi kunye nomatshini. Iguqula idatha eluhlaza evela kwiisensa kunye neenethiwekhi zolawulo ibe yingqiqo esebenzisekayo, inciphisa amaxesha okuphendula kwiingxaki zokuxilonga kunye nee-alamu.

Olu dibaniso luvumela ukugcinwa kwangaphambili. I-PLC inokulandelela amakhulu eengongoma zedatha, njengokungcangcazela kwemoto kunye nobushushu beebheringi, kwaye ilumkise amaqela ngeengxaki ezinokubakho ngaphambi kokuba kwenzeke ukusilela. Oku kuvumela ukugcinwa kucwangciswe ngexesha lokuvalwa okucwangcisiweyo endaweni yokusabela kwiindleko eziphantsi. Imbuyekezo kolu tyalo-mali idla ngokuba ngokukhawuleza kwaye ibalulekile.

| Inkampani | Inkqubo Iphunyeziwe | Ukuncitshiswa kweendleko zokusebenza | Ukwanda kwemveliso |

| I-SteelTech Inc. | Ukulandelela izinto ngokuzenzekelayo, ukugcinwa kwangaphambili | 15% | 20% |

| Umenzi weNsimbi | Inkqubo yolawulo lwamandla oluzenzekelayo | 3% ngonyaka | Ukunyuka komgangatho we-1.35% |

Ukuphucula iiDrives kunye neeNkqubo zoMatshini

Izixhobo ezibonakalayo zomgca zibaluleke kakhulu njengenkqubo yawo yokulawula.izinto zoomatshiniziimeko ezixhaphakileyo zokungaphumeleli, nto leyo ekhokelela ekungacwangcisweni kwexesha lokungasebenzi kunye nomgangatho wemveliso ongaguqukiyo.

Uphuculo oluphambili kukutshintsha ukusuka kwii-DC drives ezindala ukuya kwii-AC vector drives zanamhlanje. Ii-AC drives zibonelela ngokusebenza okuphezulu kunye neendleko eziphantsi zobomi. Zigcina amandla angcono kakhulu kuzo zonke isantya, zinciphisa ukusetyenziswa kwamandla ukuya kuthi ga kwi-15% kwezinye iimeko.

| Uhlobo lweDrive | Imfuneko yoLondolozo | Ukuthembeka |

| Ii-AC Drives | Iphantsi (akukho bhrashi okanye izinto zokuhamba) | Uyilo oluphezulu (oluqinileyo) |

| IiDrives zeDC | Phezulu (iibrashi kunye nee-commutators) | Ezantsi (kuxhomekeke ekugugeni koomatshini) |

Ngaphezu koko, iimoto ze-AC zilungele ngcono indawo enothuli yesixhobo sokugalela igesi. Uyilo lwazo olupholileyo ngaphandle luthintela ungcoliseko, ngokungafaniyo neemoto ze-DC ezipholileyo ngaphakathi ezifuna umoya ohluziweyo. Iitekhnoloji ezifana ne-Direct Torque Control (DTC) zinika iimoto ze-AC isantya esichanekileyo kunye nolawulo lwe-torque, zihlala zisusa imfuneko yezixhobo zokuphendula zangaphandle.

Ukusilela koomatshini, ingakumbi ukwaphuka kwamalungu okuwelda, kunokumisa umgca ukuya kuthi ga kwiiyure ezingama-48. Oku kusilela kudla ngokubangelwa ziiparameter zokuwelda ezingafanelekanga okanye ukudinwa kwezinto. Ukulwa noku, abaphathi kufuneka batyale imali kwizinto eziqinileyo zoomatshini. Ukuphucula iibheringi ze-pot roll luphuculo olunempembelelo enkulu.

| Uhlobo loPhuculo | Izinto/Uqwalaselo | Uphuculo Lokusebenza |

| Izinto zokuthwala | Iingubo ze-Al2O3 (Alumina) | Ukumelana nokugqwala okuphezulu kwiibhafu zeZn-Al kunye neZn-Al-Mg. |

| Uqwalaselo lweeBheri | Ukubhangqa i-SS 316L egqunywe nge-Al2O3 kunye neWallex6TM | Uqwalaselo olunokwenzeka lokuphucula ukuqina nokusebenza. |

Hlanganisa uLawulo loMgangatho oluPhambili

I-Galvanizing Production Line Factory yanamhlanje isusa ulawulo lomgangatho ukusuka kwinqanaba lokugqibela lokuhlola ukuya kwinkqubo edibeneyo, yexesha langempela. Olu tshintsho lunciphisa ukulahla, lugcina izinto eziluhlaza, kwaye luqinisekisa ukuba yonke imveliso iyahlangabezana nemigangatho engqongqo.

Ukuhlolwa komphezulu ngokuzenzekelayo sisiseko solawulo lomgangatho lwanamhlanje. Ezi nkqubo zisebenzisa iikhamera zokubona ezisebenzisa i-AI kunye nesisombululo esiphezulu ukubona iziphene ngexesha langempela ngesantya esifikelela kwi-1,200 yeemitha ngomzuzu. Ziyakwazi ukuchonga:

- Ukwambathiswa kwezinki okungalinganiyo

- Amabala omhlwa kunye ne-oxidation

- Iimbobo kunye neengxobo zepinki

- Imiqolo kunye nemikrwelo engaphezulu

Olunye uphuculo olubalulekileyo kukuhlanganiswa kweegeyiji zobunzima bokugquma ngexesha langempela. Ezi sensors zingatshabalalisiyo zihlala zijonga ukugquma kwe-zinc ngexesha lokuveliswa. Oku kuvumela ukulungiswa okukhawulezileyo, ngokuzenzekelayo kwiimela zomoya, ukuqinisekisa ukugquma okufanayo okuhlangabezana neemfuno ngaphandle kokugquma okubiza kakhulu. Isiphumo sokonga okukhulu kwe-zinc, ukuhambelana okuphuculweyo kwemveliso, kunye nemveliso ephezulu iyonke.

Ezi teknoloji zinceda amaziko ukuba ahlangabezane nemigangatho ephambili yoshishino yomgangatho kunye nenkangeleko.

Imigangatho ephambili ibandakanyaI-ASTM A123/A123Mkwiimveliso zentsimbi kunye nentsimbi kunyeI-ISO 1461kwiindibano ezenziweyo. Ukunamathela kwezi zinto kuqinisekisa ukwamkelwa kwemarike yehlabathi.

Ngokudibanisa ezi nkqubo ziphambili, abaphathi baguqula ulawulo lomgangatho ukusuka kwiziko leendleko ukuya ekubeni ngumqhubi wexabiso, nto leyo ephucula udumo lwebhrendi kunye nolwaneliseko lwabathengi.

Inyathelo lesi-3: Cwangcisa kwaye Uqalise iProjekthi yoHlaziyo

Uphuculo oluphumelelayo luxhomekeke ekucwangcisweni nasekusetyenzisweni ngononophelo. Eli nyathelo liguqula uphicotho-zincwadi kunye nezinto eziza kuqala kwezobuchwepheshe zibe yisicwangciso esicacileyo sokwenza izinto, linciphisa ukuphazamiseka kwaye liphucule imbuyekezo kutyalo-mali.

Phuhlisa iShedyuli yokuSebenza ngokweSigaba

Abaphathi kufuneka baphephe ukuvalwa ngokupheleleyo kweprojekthi ngokuyihlulahlula ibe ngamanqanaba alawulekayo.ukuphuculwa ngokupheleleyokungathatha iminyaka; umzekelo, isityalo esinye siphinde safaka ii-drives zaso kwixesha leminyaka emihlanu. Le ndlela ivumela umsebenzi ukuba wenzeke ngexesha lekhefu elifutshane nelicwangcisiweyo lemveliso. Isicwangciso esicacileyo siquka amanyathelo aliqela:

- Yahlulahlula iprojekthi ibe ngamacandelo amancinci, njengeemodyuli okanye iimpawu.

- Vavanya ubunzima benxalenye nganye (umz., encinci, ephakathi, enkulu).

- Beka izinto ezibalulekileyo kwindawo yazo ngokusekelwe kwixabiso leshishini kunye nomngcipheko.

- Hlanganisa izinto zibe ngamanqanaba afanelekileyo ukuze ulinganisele umthwalo womsebenzi.

- Hlela isigaba ngasinye ngeziganeko ezicacileyo kunye neziganeko ezibalulekileyo.

Lawula iingozi zeProjekthi kunye neeNgxaki

Yonke iprojekthi ineengxaki ezinokubakho. Ulawulo lomngcipheko olusebenzayo lukhusela ixesha kunye nohlahlo-lwabiwo mali. Abaphathi kufuneka bachonge iziganeko ezinokubakho zexesha lokungasebenzi kwaye benze iinkqubo zokuphendula ezineenkcukacha. Ukusebenzisa idatha evela kwiinkqubo zokulungisa eziqikelelweyo kunceda ukwenza ezi zicwangciso zexesha lokungabikho kwemisebenzi zichaneke ngakumbi.

| Umngcipheko onokubakho | Icebo Lokunciphisa Ingxaki |

| Ixesha lokuphumla elingalindelekanga | Yenza iqela elizinikeleyo lokuphendula elineendima ezicacileyo. |

| Ukulibaziseka kweCandelo loNikezelo | Gcina uluhlu lwezinto ezibalulekileyo ezingasetyenziswanga. |

| Iingxaki zeZixhobo | Yila izicwangciso eziqinileyo zokujongana neengxaki ezingalindelekanga. |

Sebenzisa uvavanyo lwangaphambili kunye novavanyo olungekho kumgca

Ukunciphisa ixesha lokufakwa kwindawo, amaqela anokwakha izinto kwindawo elawulwayo yefektri. Ukwakha izinto ezinje ngeentambo zocingo kunye neendawo zokulawula kuvumela ukuba kubekho imisebenzi ehambelanayo, njengoko umsebenzi wesiseko kwindawo unokwenzeka ngaxeshanye. Eli cebo linciphisa inkunkuma yokwakha kwaye linciphisa ixesha leprojekthi iyonke.

Ngaphambi kokuba nayiphi na inkqubo entsha isebenze, kufuneka ivavanywe ngaphandle kwe-intanethi. Uvavanyo loKwamkelwa kweFactory (FAT) luqinisekisa ukuba inkqubo isebenza njengoko yayilwe. Le nkqubo ibamba uninzi lweengxaki ngaphambi kokuba izixhobo zifike ebaleni, nto leyo esindisa ixesha nemali eninzi ngexesha lokuqaliswa kokusebenza. ✅

Inyathelo lesi-4: Lungiselela uMzi-mveliso wakho woMgca weGalvanizing ophuculweyo

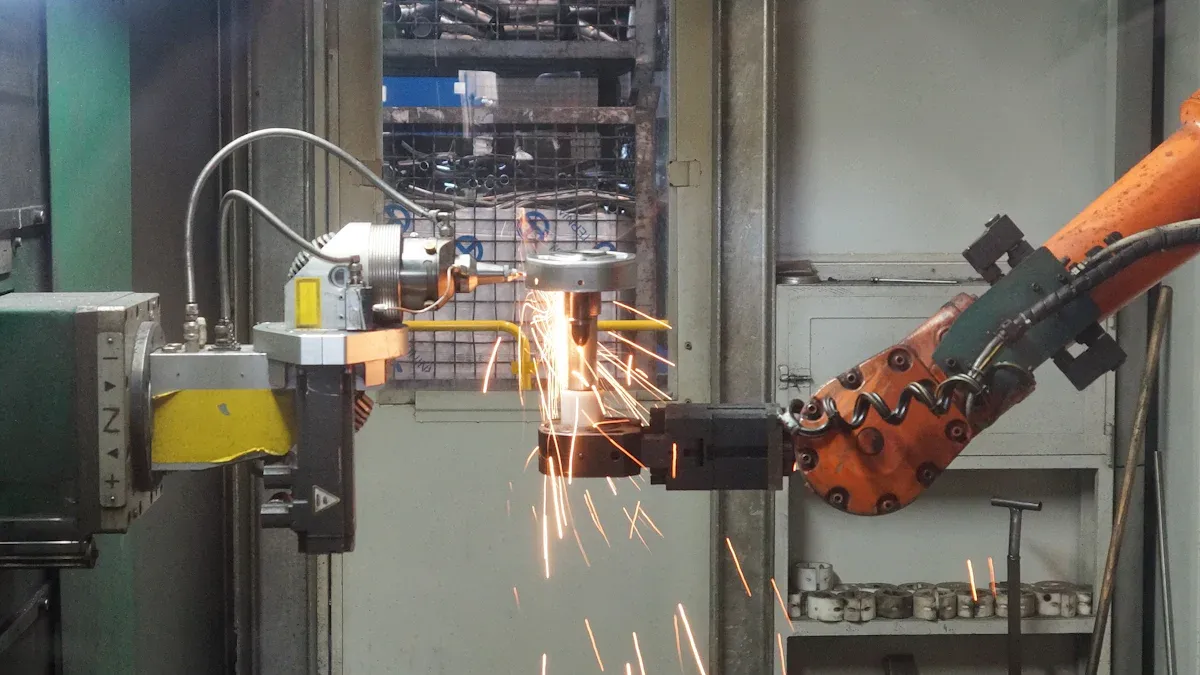

Umthombo womfanekiso:susa iplastikhi

Ukuphucula izinto akupheleli ngokufakela. Inyathelo lokugqibela kukuphucula isici somntu. Oku kuqinisekisa ukuba iteknoloji entsha inika amandla ayo apheleleyo. Uqeqesho olufanelekileyo, iinkqubo ezihlaziyiweyo, kunye nenkcubeko yokucinga kwangaphambili zibalulekile kwimpumelelo yexesha elide.

Qeqesha Abasebenzi kwiiNkqubo Ezintsha

Itekhnoloji entsha ifuna izakhono ezintsha. Abaphathi kufuneka banike uqeqesho olupheleleyo kubo bonke abasebenzi. Oku kulungiselela amaqela ukuba asebenzise ezintshaiinkqubo zokwenza izinto ngokuzenzekelayongokufanelekileyo. Uqeqesho olusebenzayo ludibanisa imiyalelo yobugcisa kunye neeworkshops ezisebenzayo kunye nokulinganisa. Le ndlela yakha ukuzithemba kwabaqhubi kwindawo ekhuselekileyo nelawulwayo. Abasebenzi bolondolozo abaqeqeshwe kakuhle banikezela ngeenzuzo ezibalulekileyo:

- Ukuchonga ingxaki ngokukhawuleza

- Ukunciphisa ixesha lokuphumla elingacwangciswanga

- Ukuphucula ubude bexesha lezixhobo

- Uzinzo oluphuculweyo lokusebenza

Uqeqesho oluqhubekayo lubalulekile. Lunceda amaqela ukuba ahambelane nophuhliso lwetekhnoloji olukhawulezayo. Olu kuzinikela luqinisekisa ukuphuculwaUmzi-mveliso woMgca weMveliso yeGalvanizingihlala isebenza kakuhle kwaye ikhuphisana.

Hlaziya iinkqubo zokusebenza eziqhelekileyo

Izixhobo zanamhlanje zenza iinkqubo ezindala zingasebenzi. Amaqela kufuneka ahlaziye iiNkqubo zokuSebenza eziMiselweyo (ii-SOP) ukuze zibonise iinkqubo ezintsha zokusebenza nezokhuseleko. Oku kuquka ukubhala phantsi ukusetyenziswa kwezixhobo ezintsha, iimpendulo ezingxamisekileyo, kunye neeshedyuli zokugcinwa rhoqo. Ukhuseleko lolona luphambili.

| Uhlaziyo loKhuseleko | Kufuneka isenzo |

| Ukuhlolwa Kwangaphambi Kokusebenza | Yenza uhlolo lwemihla ngemihla ukuze ubone ukuba akukho nto igugileyo, ayivuzi, okanye ayisebenzi kakuhle. |

| Iimpawu zoKhuseleko | Abaqhubi besitimela bazivalela ngokuzenzekelayo kunye nezinzwa. |

| Izikhokelo zoMvelisi | Landela ngokungqongqo zonke iincwadi zokusebenza kunye nokugcinwa kwazo. |

| Izixhobo zoKhuseleko loBuqu (i-PPE) | Qinisekisa ukuba bonke abasebenzi banxiba izixhobo ezifanelekileyo ezifana neminqwazi eqinileyo kunye neeglasi zokhuseleko. |

Khuthaza Inkcubeko Yokuphucula Okuqhubekayo

Eyona njongo iphambili yinkcubeko yokuphucula okuqhubekayo. Ubunkokeli kufuneka bukhuthaze le ndlela yokucinga. Banokubandakanya abasebenzi kuwo onke amanqanaba kwaye bakhuthaze izimvo zokuphucula ngakumbi. I-Galvanizing Production Line Factory yanamhlanje iphumelela kwimpendulo.

Abasebenzi beShift banolwazi olucacileyo ngeengxaki kunye nokungasebenzi kakuhle. Ingxelo yabo inika ulwazi olubalulekileyo lokusebenza olunokukhuthaza ukuphuculwa kwenkqubo kunye nokuvelisa izinto ezintsha.

Abaphathi kufuneka bamisele iindlela ezicacileyo zokuphendula. Oku kuvumela abasebenzi ukuba babone iingxaki baze bacebise izisombululo. Ukubhiyozela impumelelo kunye nokwenza ngokweempendulo kuqinisa inkcubeko apho ilungu ngalinye leqela linegalelo ekwenzeni ngcono okuqhubekayo. ✅

Uphuculo oluphumelelayo lulandela indlela ecacileyo.

- Iqala ngokuhlolwa ngokucokisekileyo ukuze kufunyanwe ubuthathaka obuthile.

- Abaphathi bagxila kutyalo-mali kwiindawo ezinengeniso ephezulu njengokwenziwa kwezinto ngokuzenzekelayo.

- Isicwangciso esicwangcisiweyo sinciphisa ixesha lokungasebenzi ngexesha lokwenziwa.

Eyona njongo iphambili kukusebenza okusebenzayo, okunenzuzo, nokukhuphisanayo, kungekuphela nje kwezixhobo ezintsha.

Ixesha leposi: Oktobha-21-2025